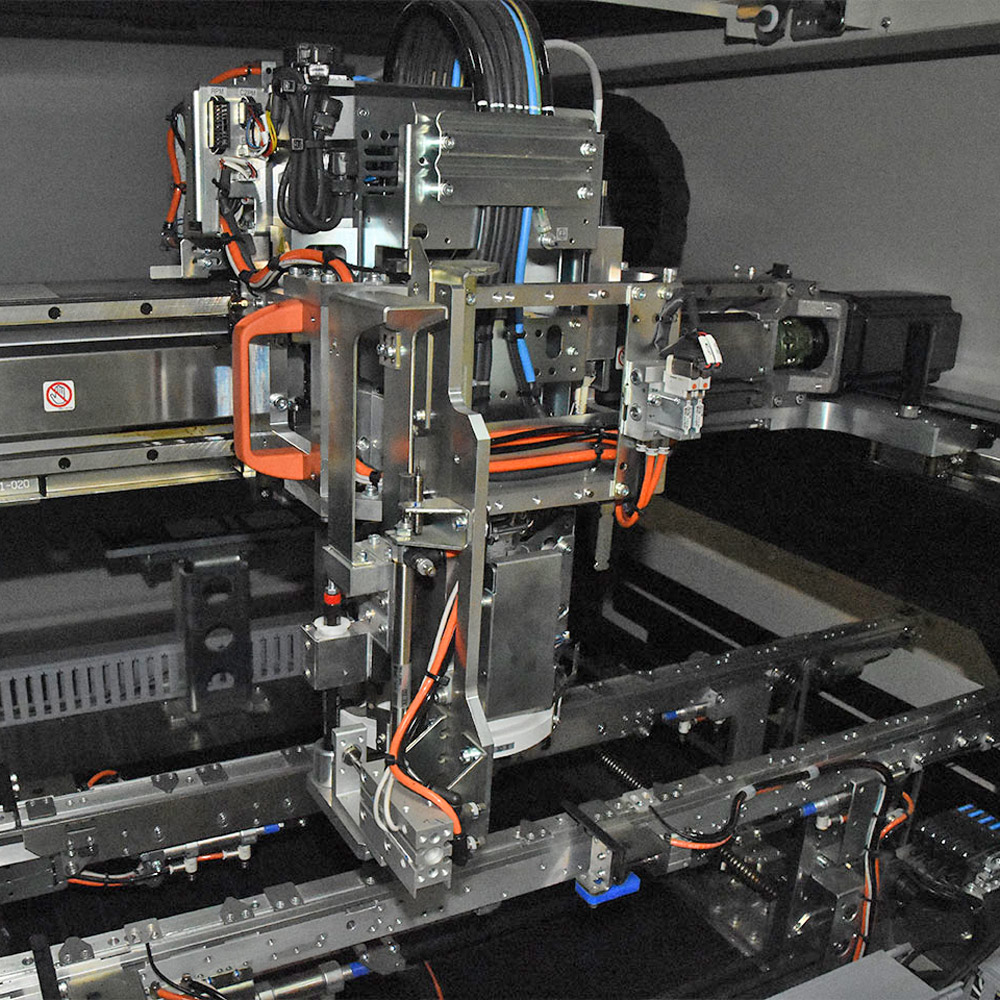

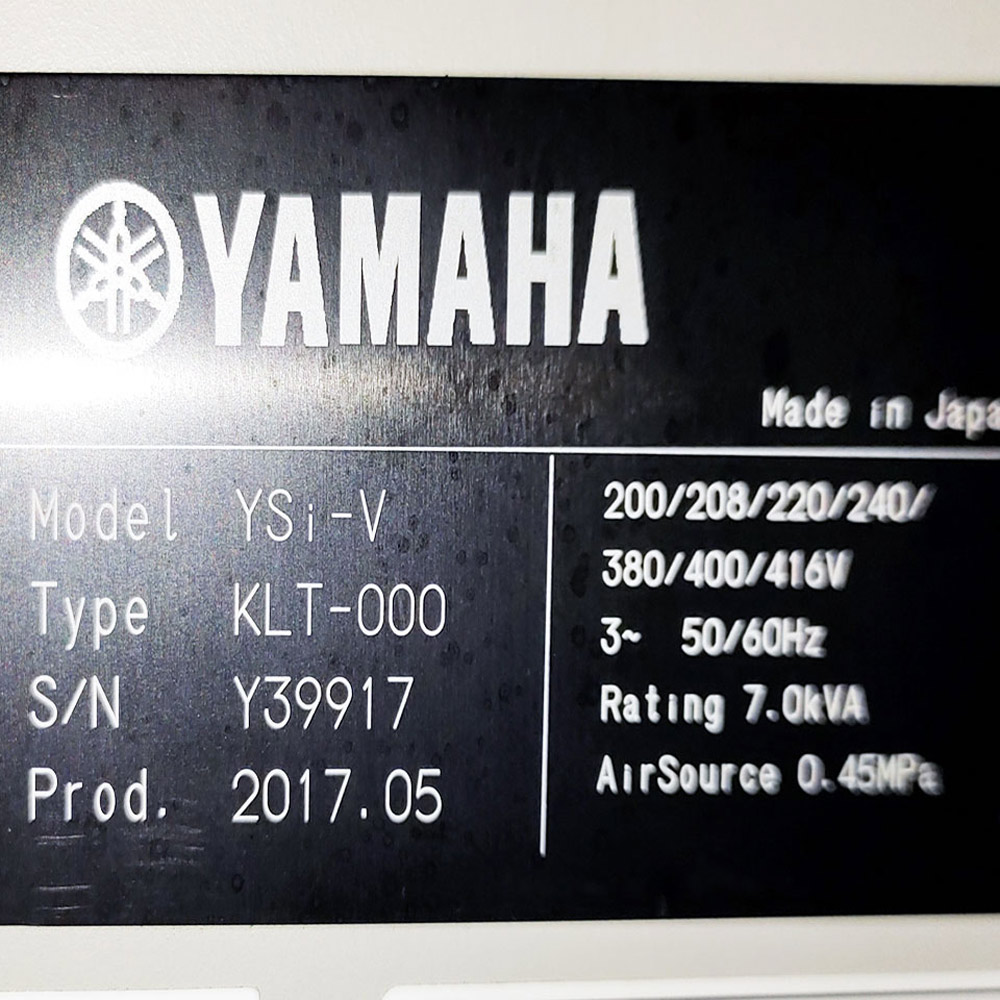

YSi-V

High-End Hybrid Optical Inspection System (AOI)

Unique features ensure accurate inspection results and high efficiency, for optimum productivity.

12MP or 5MP

2D and 3D

INQUIRE NOW >>>

High-speed, high-resolution 2-dimensional inspections

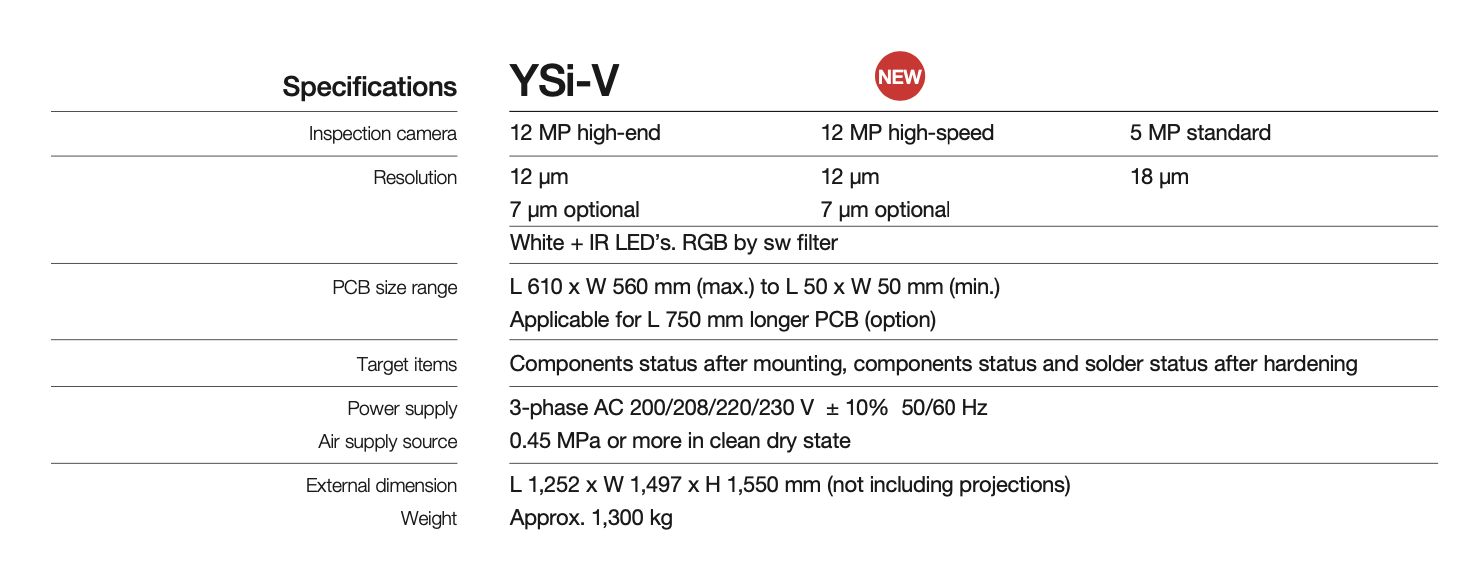

YSi-V is available in a standard type with a 5 MP camera or as a high-end type with a 12 MP camera. The 12 MP camera along with a telecentric lens supports a high number of pixels. It also incorporates a high-speed signal processing control system and other features to achieve an inspection capability twice that of ordinary units along with an expanded visual field, superior image resolution, and high speed.

Laser

Detects height.

Example: floating lead detection. Note: laser is provided as an option.

Shape

Extracts sloped sections. Example: detection of solder fillet.

Brightness

Selective brightness adjustment of captured image enhances inspection for missing components, polarity, component ID by character recognition.

Infrared

Shows white components on white resist.

Brightness

Selective brightness adjustment of captured image enhances inspection for missing components, polarity, component ID by character recognition.

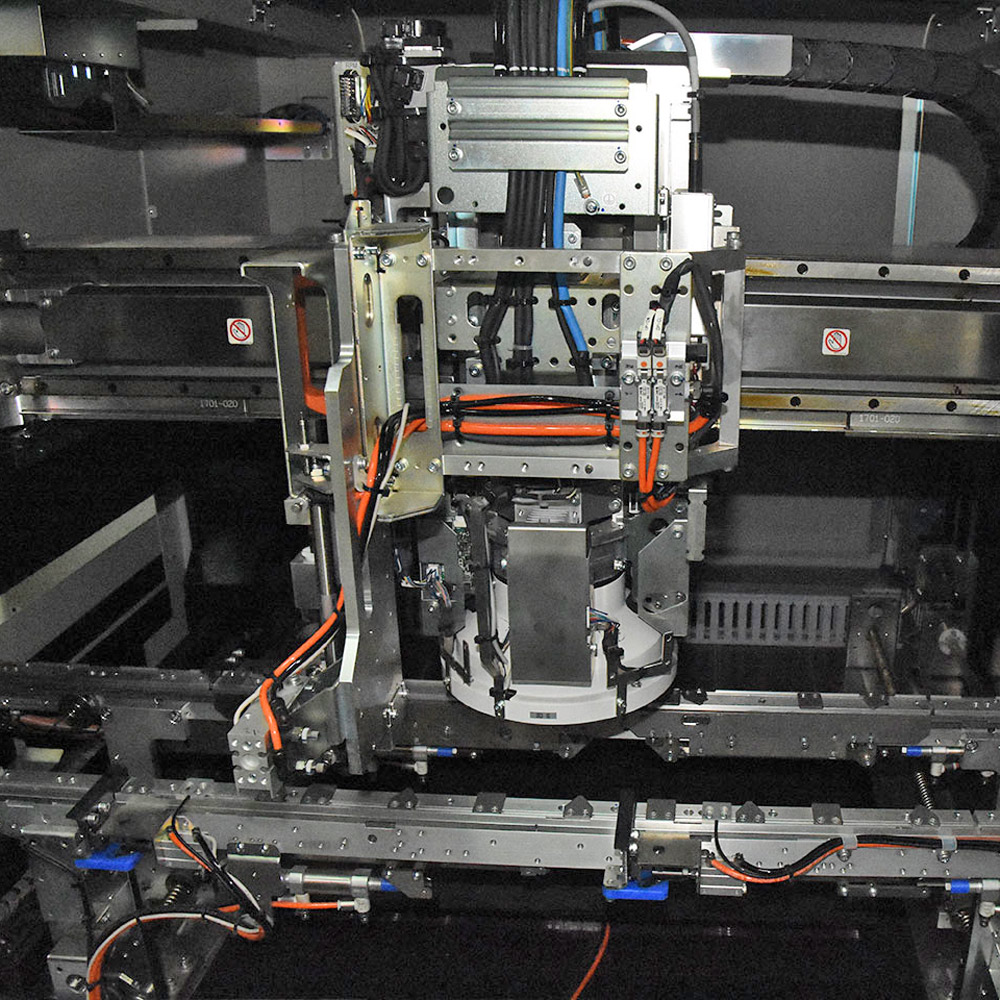

Height and sloped surface 3-dimensional inspections (option)

YSi-V makes high-speed height measurements within an entire field of view, in one batch. This 3D imaging reliably detects floating components that a 2D inspection can miss. Detection is also improved where color tones between board and components are similar or when there is interference between silk-screen and pattern. YSi-V 3D inspection can also detect the slope gradient and direction, and make pass/fail contour judgements.

Detection of extra components or contamination as solder ball or black material.

Based on luminance or by 3D height detection.

Angular inspection

Besides the orthogonal inspection, YSi-V can do angular inspection from four directions (45°, 135°, 225°, 315°). You can isolate a component and inspect it as if looking at the board from four different angles without removing the board from the line. This minimizes human intervention with boards, thereby eliminating errors and reducing the number of process steps.

Supports and easy creation of inspection programs!

Loads Yamaha mounter data for import into inspection data. A preinstalled library of over 1,000 types drastically shortens the startup time. Also supports IPC standards (IPC-A-610), and just specifying the particular class automatically updates the inspection standards. Auto tuning of the inspection window size based on pad size.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top