Wholesale Hitachi Nozzle Products – JUKI KE-2060M SMT PLACEMENT, CHIP MOUNTER, PICK AND PLACE MACHINE, USED SMT EQUIPMENT – RHSMT Detail:

KE-2060M

High-speed flexible mounter

All-round surface mounter with Yamaha’s 1-head solution delivers superior productivity and versatility!

INQUIRE NOW FOR MORE DETAIL >>>

Features

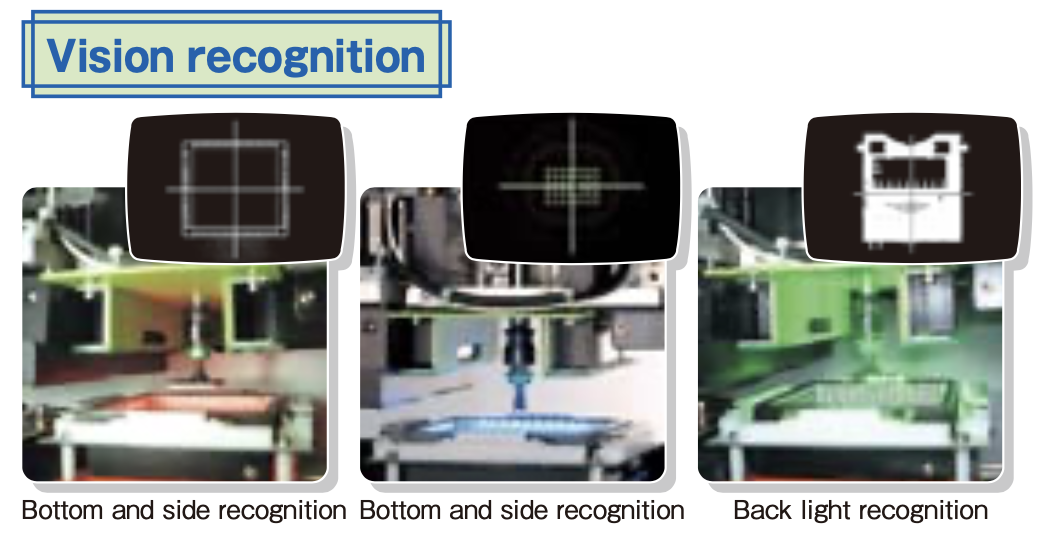

JUKI’s unique component recognition system Dual use of laser and vision (featuring bottom, side, and back lighting) recognition systems.

Recognition method can be chosen for chip placement, based on the shape, size and material of components. Laser for high-speed placement and vision for flexible placement. With the combination of nozzles designed for odd-shaped components and the vision recognition system, the KE-2060s component placement capability is unsurpassed.

General Vision function is used to support a wide variety of today’s unique and vision centered components. While programming, the data input can be verified for completion on the preview monitor. Additionally, component outer recognition, selection of lines or corners of components can be viewed on the monitor, providing further ease of operation and data entry.

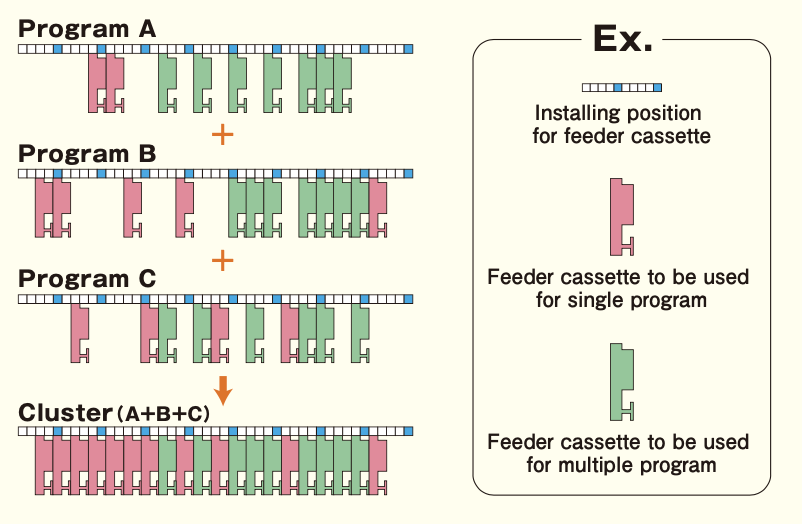

Cluster Optimization

A “Cluster” is a group of feeders that can be used for more than one production file. The feeders required for several different production files are grouped into a single feeder configuration, or cluster, thus eliminating the need for change over between different boards. The clustered feeders, which are used on more than one production file are assigned first, then other feeders, which are used on single program are set assigned.

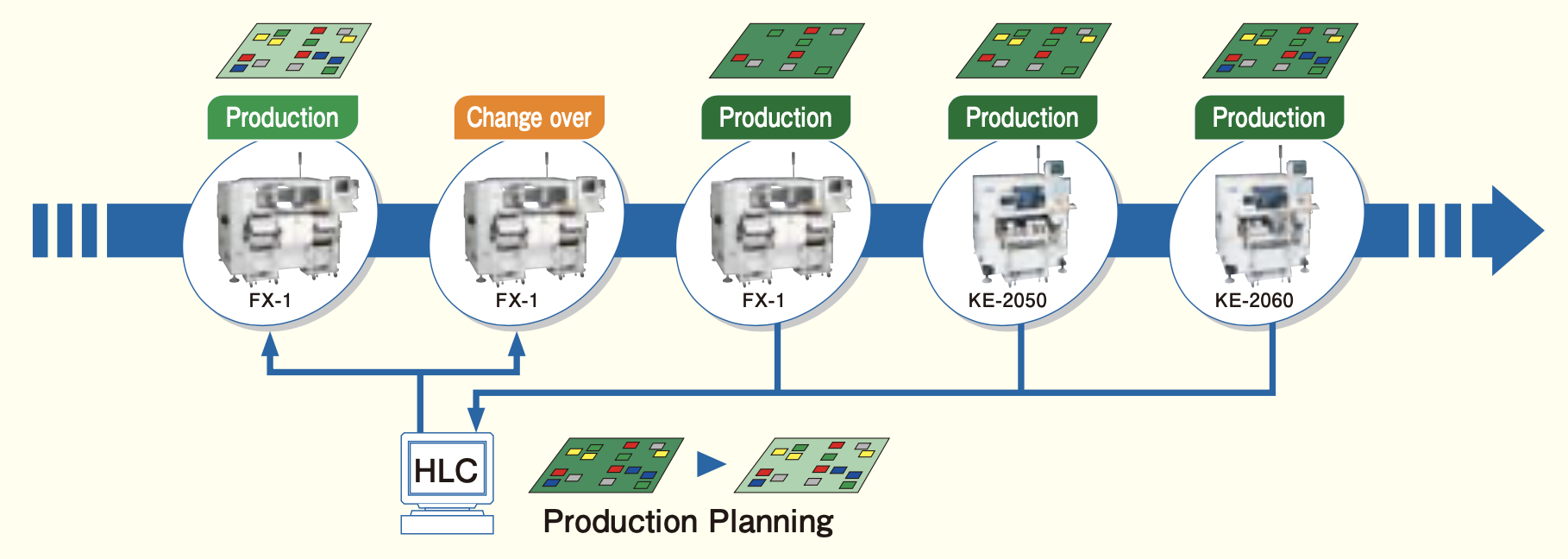

Auto Production Download

The production data is automatically uploaded into HLC from the machine, when placement is completed, and HLC software automatically downloads the next production program into the machine. Once change over is completed, the machine starts placing of the next program.

Why Choose US?

Massive resources

We have in-depth cooperation with major SMT brands, most of the SMT equipment is in stock and can be shipped immediately

Quality assurance

All used equipment is tested, aged, and serviced before shipping. Vacuum packing in wooden boxes ensures safe delivery of equipment to you.

Secure transactions

We support flexible payment methods and a 6-month machine warranty to relieve your worries.

Trusted partner

We have many years of experience in the SMT field and are active members of IPC, your trusted partner!

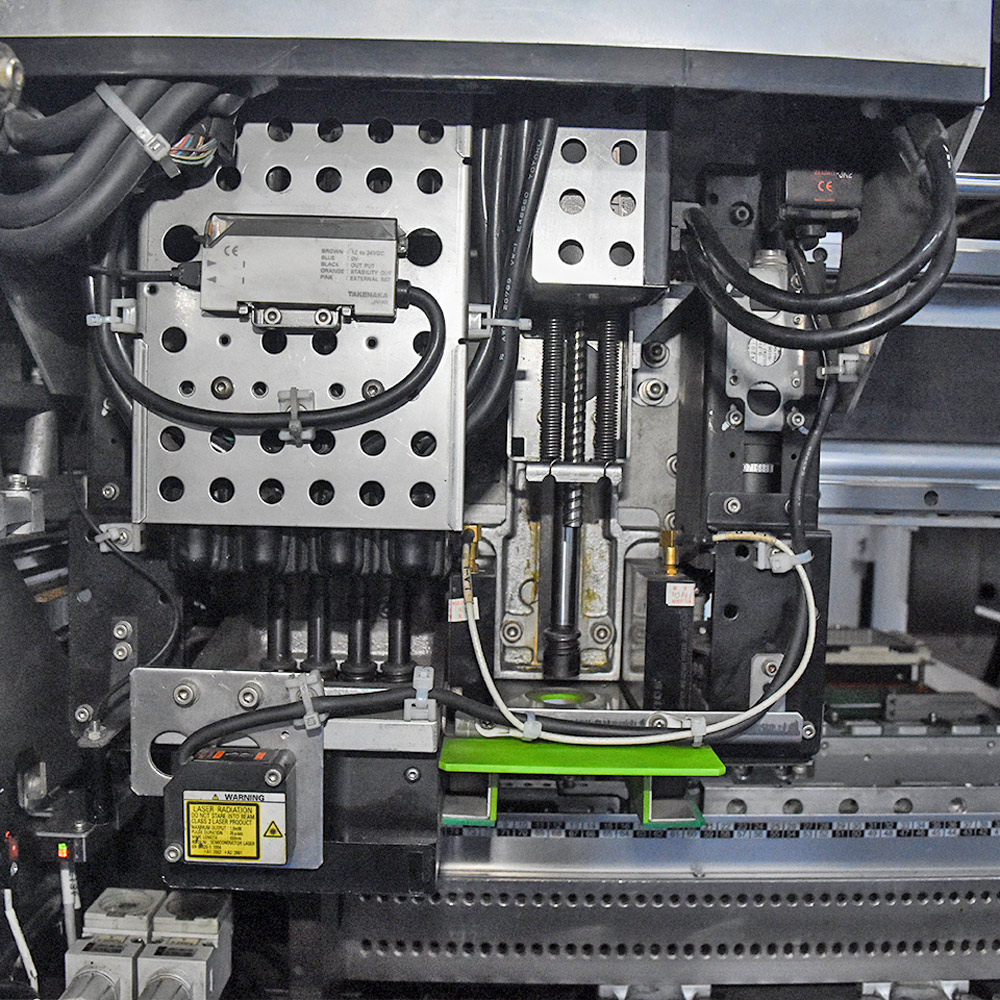

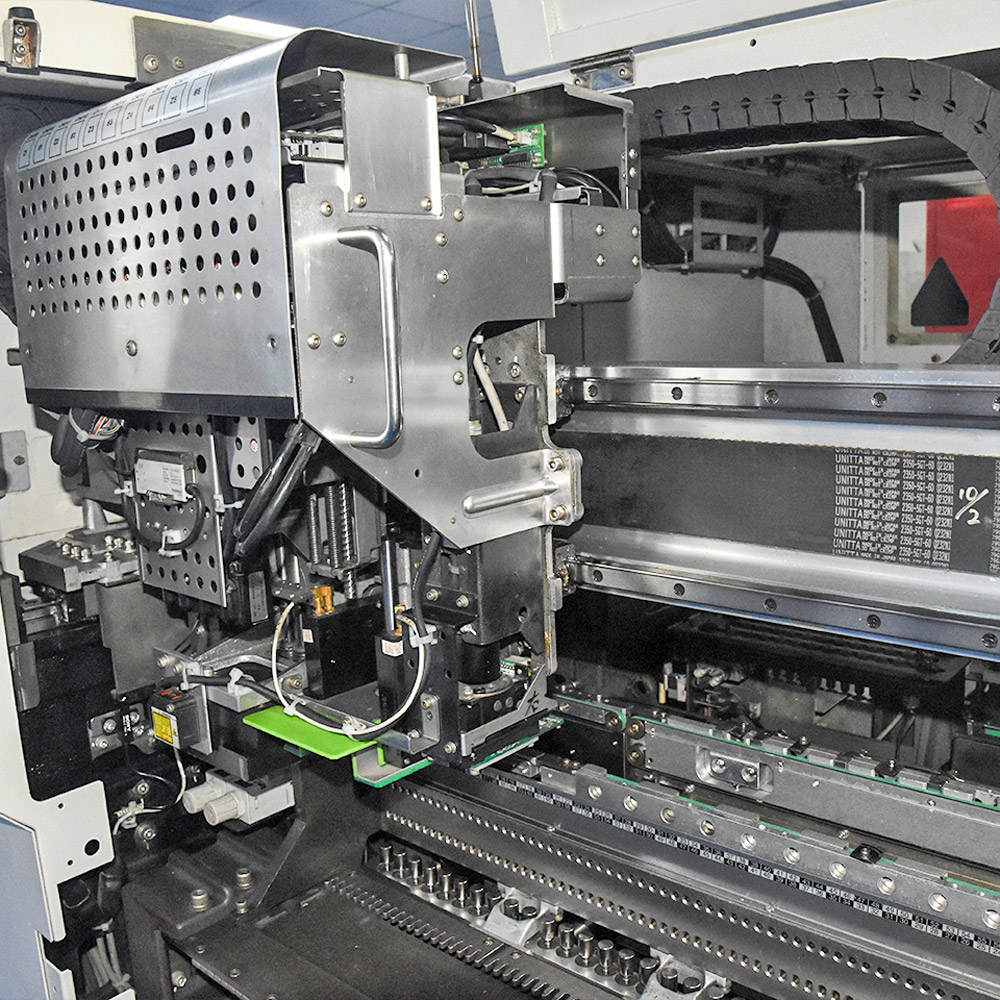

Product detail pictures:

Related Product Guide:

We have now our possess revenue group, design staff, technical crew, QC team and package group. We now have strict excellent regulate procedures for each process. Also, all of our workers are experienced in printing subject for Wholesale Hitachi Nozzle Products – JUKI KE-2060M SMT PLACEMENT, CHIP MOUNTER, PICK AND PLACE MACHINE, USED SMT EQUIPMENT – RHSMT , The product will supply to all over the world, such as: Sevilla , Lisbon , Lebanon , They are sturdy modeling and promoting effectively all over the world. Never ever disappearing major functions within a quick time, it's a have to in your case of fantastic good quality. Guided by the principle of Prudence, Efficiency, Union and Innovation. the corporation. ake an excellent efforts to expand its international trade, raise its organization. rofit and raise its export scale. We've been confident that we've been going to have a bright prospect and to be distributed all over the world in the years to come.

As an international trading company, we have numerous partners, but about your company, I just want to say, you are really good, wide range, good quality, reasonable prices, warm and thoughtful service, advanced technology and equipment and workers have professional training, feedback and product update is timely, in short, this is a very pleasant cooperation, and we look forward to the next cooperation!

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top