FEATURES

Higher productivity and quality with printing, placement and inspection process integration

Depending on the PCB you produce, you can select High-speed mode or High-accuracy mode.

For larger boards and larger components

PCBs up to a size of 750 x 550 mm with component range up to L150 x W25 x T30 mm

Higher area productivity through dual lane placement

Depending on the PCB you produce, you can select an optimal placement mode - "Independent" "Alternate” or “Hybrid”

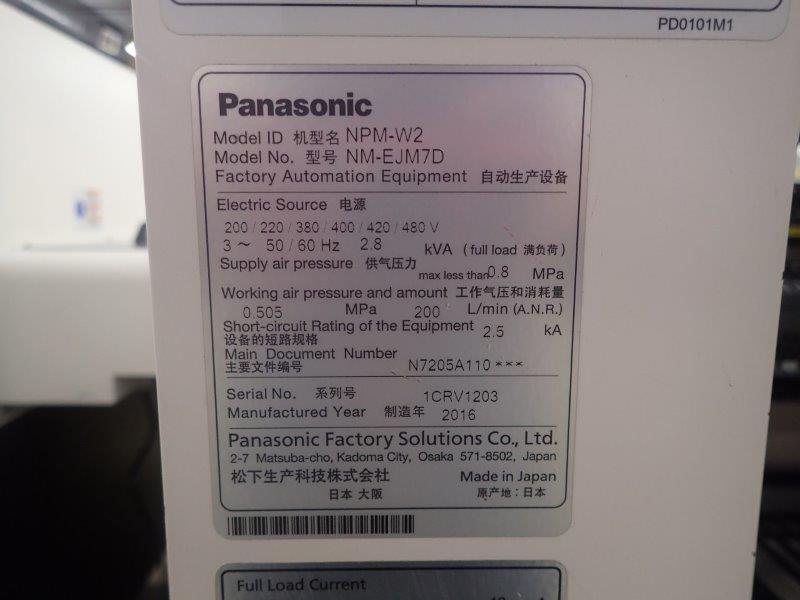

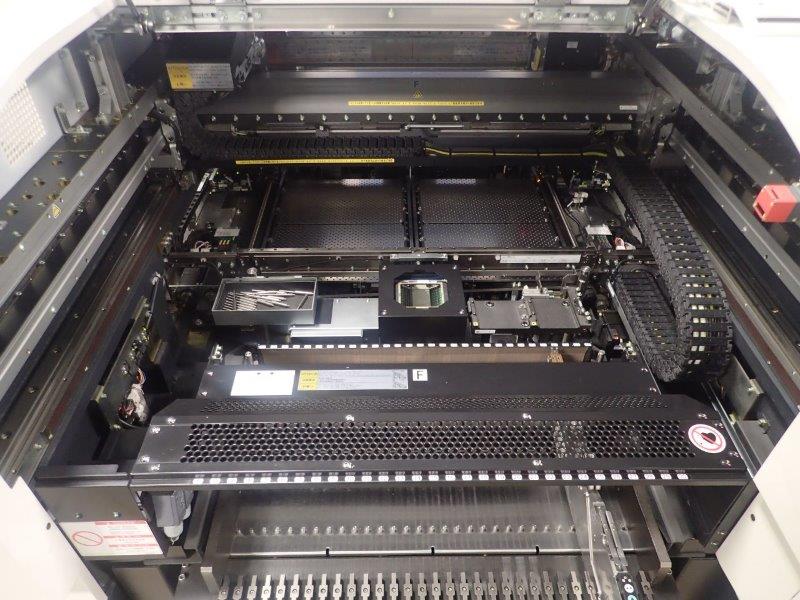

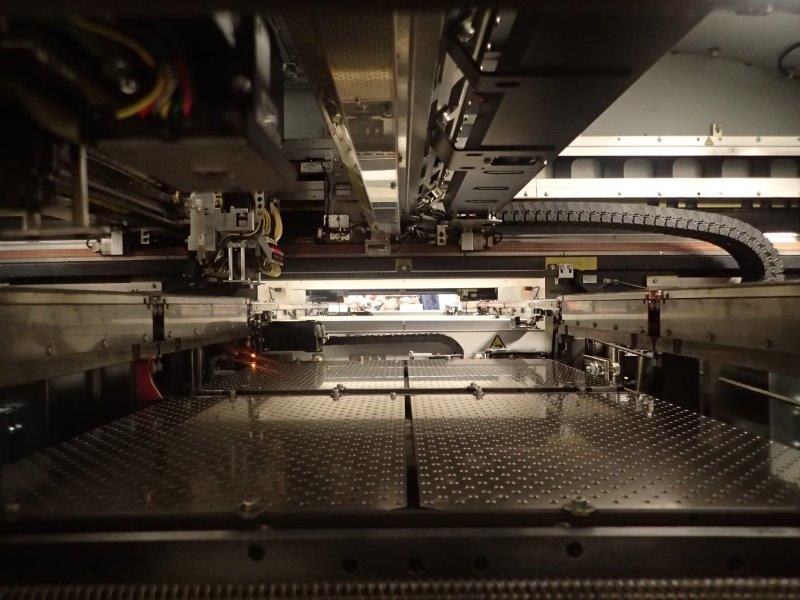

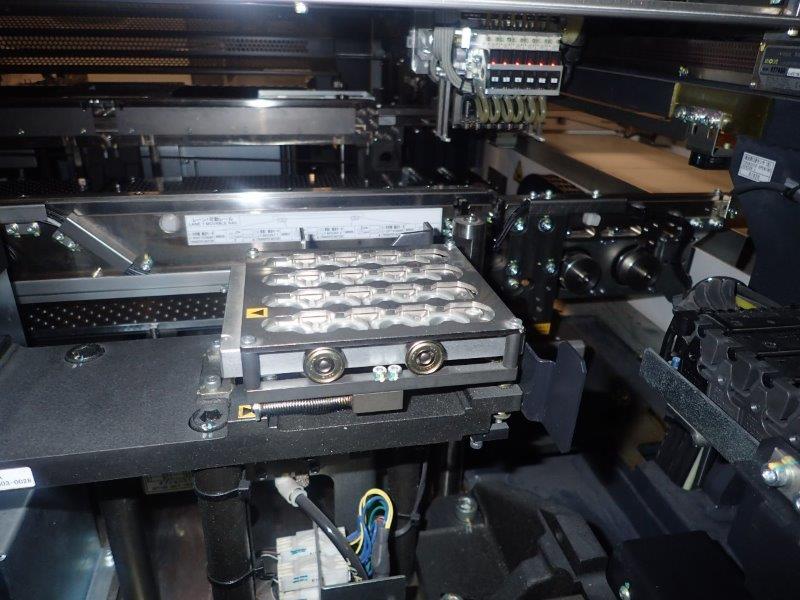

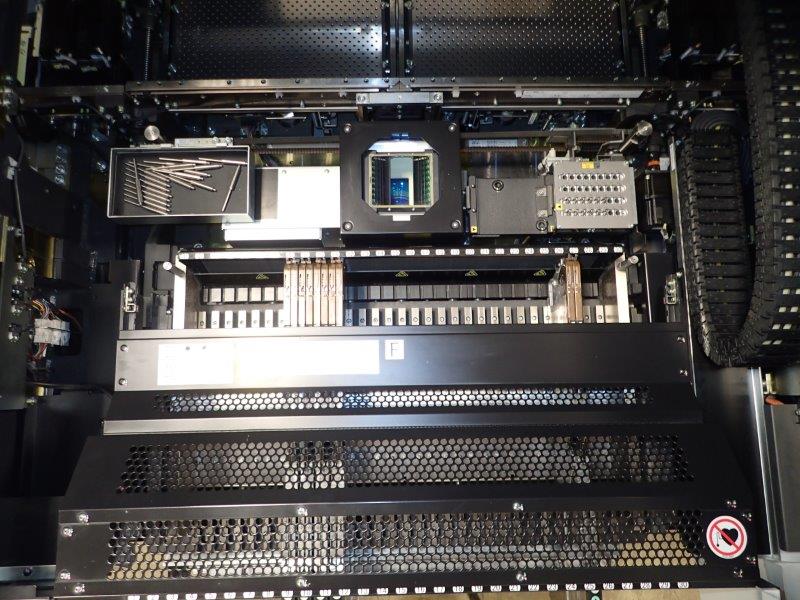

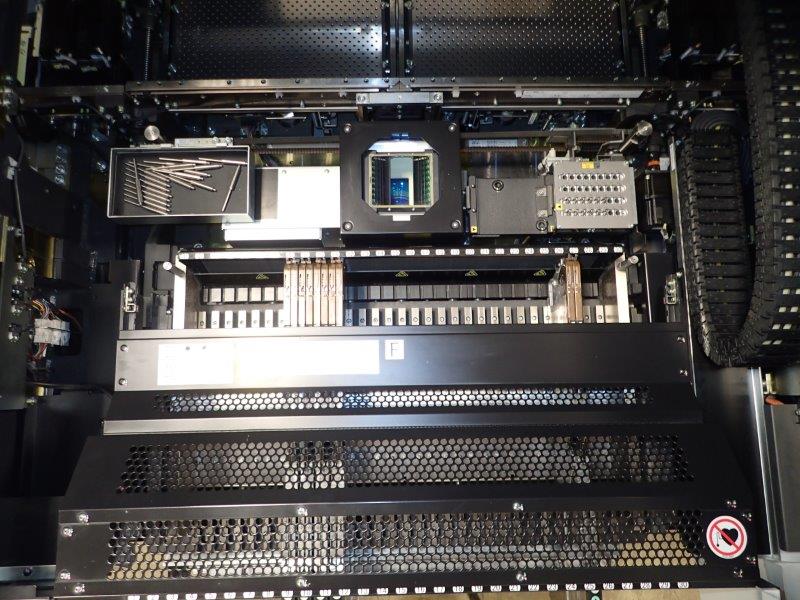

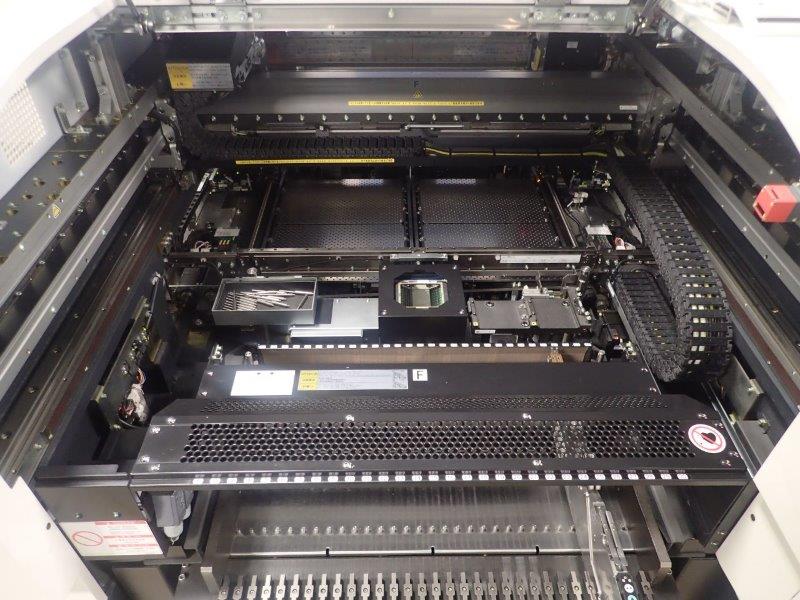

NPM-W2 PLACEMENT MACHINE DETAIL

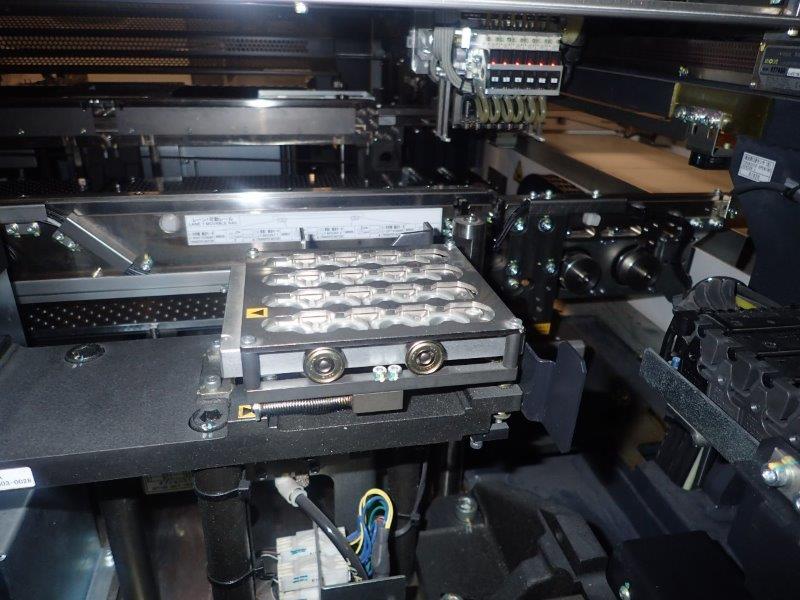

TAPE FEEDERS (Optional)

NPM-W2 FEEDER CART

(Optional)

| Placement head | Lightweight 16-nozzle head(Per head) | 12-nozzle head(Per head) | Lightweight 8-nozzle head | 3-nozzle head V2 | |||

| High production mode [ON] | High production mode[OFF] | High production mode[ON] | High production mode[OFF] | (Per head) | (Per head) | ||

| Max. speed | 38 500cph (0.094 s/ chip) |

35 000cph (0.103 s/ chip) |

32 250cph (0.112 s/ chip) |

31 250cph (0.115 s/ chip) |

20 800cph (0.173 s/ chip) |

8 320cph (0.433 s/ chip) 6 500cph (0.554 s/ QFP) |

|

| Placement accuracy (Cpk≧1) |

±40 μm / chip | ±30 μm / chip (±25μm / chip)*6 |

±40 μm / chip | ±30 μm / chip | ± 30 µm/chip ± 30 µm/QFP 12mm to 32mm ± 50 µm/QFP 12mm Under |

± 30 µm/QFP | |

| Component dimensions (mm) |

0402*7 chip ~ L 6 x W 6 x T 3 | 03015*7 *8/0402*7 chip ~ L 6 x W 6 x T 3 | 0402*7 chip ~ L 12 x W 12 x T 6.5 | 0402*7 chip ~ L 32 x W 32 x T 12 | 0603 chip to L 150 x W 25 (diagonal152) x T 30 | ||

| Component supply |

Taping | Tape : 4 / 8 / 12 / 16 / 24 / 32 / 44 / 56 mm | Tape : 4 to 56 mm | Tape : 4 to 56 / 72 / 88 / 104 mm | |||

| Max.120 (Tape: 4, 8 mm) | Front/rear feeder cart specifications : Max.120 ( Tape width and feeder are subject to the conditions on the left) Single tray specifications : Max.86 ( Tape width and feeder are subject to the conditions on the left) Twin tray specifications : Max.60 ( Tape width and feeder are subject to the conditions on the left) |

||||||

| Stick | - | Front/rear feeder cart specifications : Max.30 (Single stick feeder) Single tray specifications : Max.21 (Single stick feeder) Twin tray specifications : Max.15 (Single stick feeder) |

|||||

| Tray | - | Single tray specifications : Max.20 Twin tray specifications : Max.40 |

|||||

ABOUT PAYMENT AND SHIPMENT

ABOUT SHIPMENT

We have a variety of express delivery options for your goods, such as DHL, UPS and FedEx Express. We deliver using the quickest and cheapest way, or with the best transportation resources according to the cargo weight, volume and so on.You can relax, we will do our best to deliver your packages quickly and safely, no matter by which mode of transportation.

ABOUT PAYMENT

About payment, we accept multiple payment methods, such as T/T, Paypal, Western Union, Alipay and WeChat. Any kind of payment is official. Once your order is confirmed, we will send a photo to you as a reference before shipping.

ABOUT PACKING

Your goods are handled with great care from the time of purchase to delivery. After going through QA inspection, we use foam cotton and pearl cotton to wrap each piece of product so that it arrives at your hand in perfect condition. The vacuum bags & wooden boxes we use for packing our equipment are carefully selected to ensure no rust occurs during shipment by sea, which can cause serious damage to your equipment.

RHSMT CERTIFICATE

FAQ

One-stop SMT solution, all kinds of equipment and spare parts are available as well as technical support and repair service.

Professional QC double check before shipment, test on machine if necessary and material with warranty.

In the warranty period, non-human reasons and operating errors of quality problems, free technical support and part replacement is available, even refund.

- SMT/AI spare parts lead time: 2-3 days.

- If order from origin factory , the lead time need 4-8 weeks.

- SMT machine equipments lead time: 1-2 weeks

- SMT peripheral equipment lead time: 2-4 weeks

- The warranty period of SMT Spare parts is: 3-6 months

- The warranty period of SMT peripheral equipment is 6 months

We accept exchanges, returns. If there is a problem with the machine, we usually replace the parts for you

We cooperate with professional freight forwarding companies and can help you with customs clearance.

TT, Paypal, Western Union, LC , 100% before shipment.

Asia, Europe, USA and Brazil.

OEM&ODM service are available.

Spare parts -- Carton+ bubble cotton; Equipment -- Wooden case + vacuum sealed.

EXW, FOB, CIF, CFR, DAP ect.

By air, by sea, by train, carrier account ect.

Professional forwarder will handle shipment.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top