● Prevent dust, foreign matter, water, oil and other substances from entering the placement machine to ensure the cleanliness of each part of the placement machine so that the machine can operate normally.

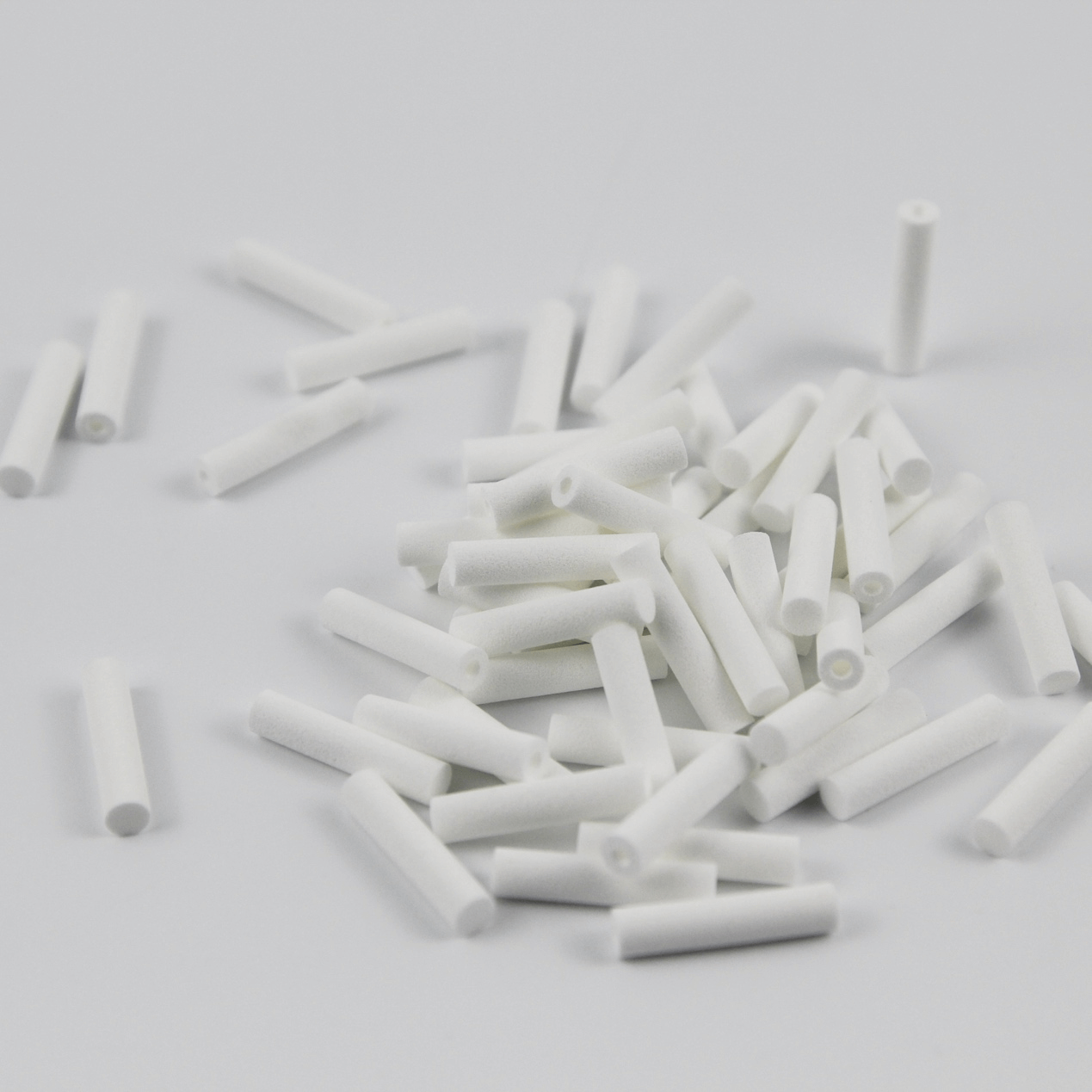

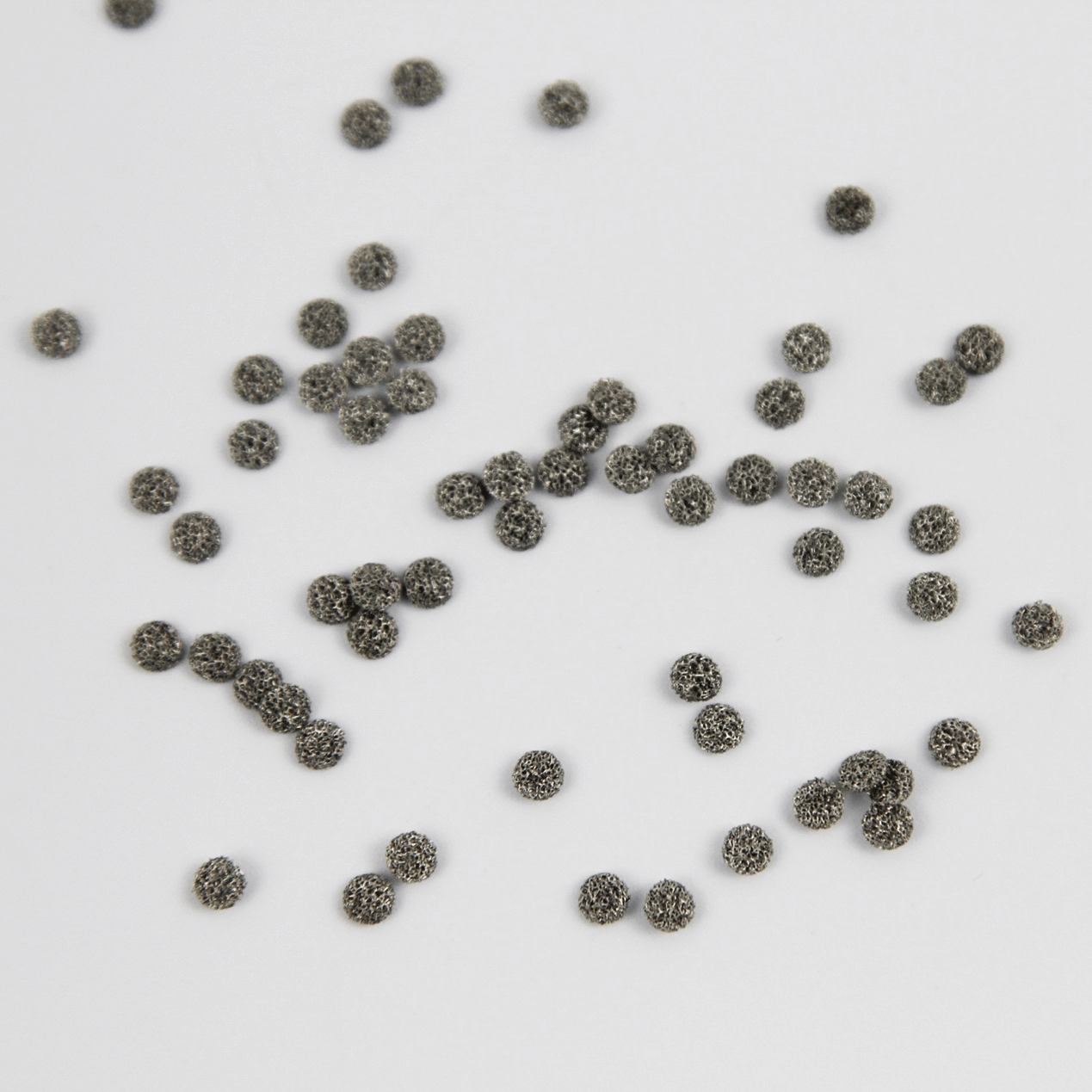

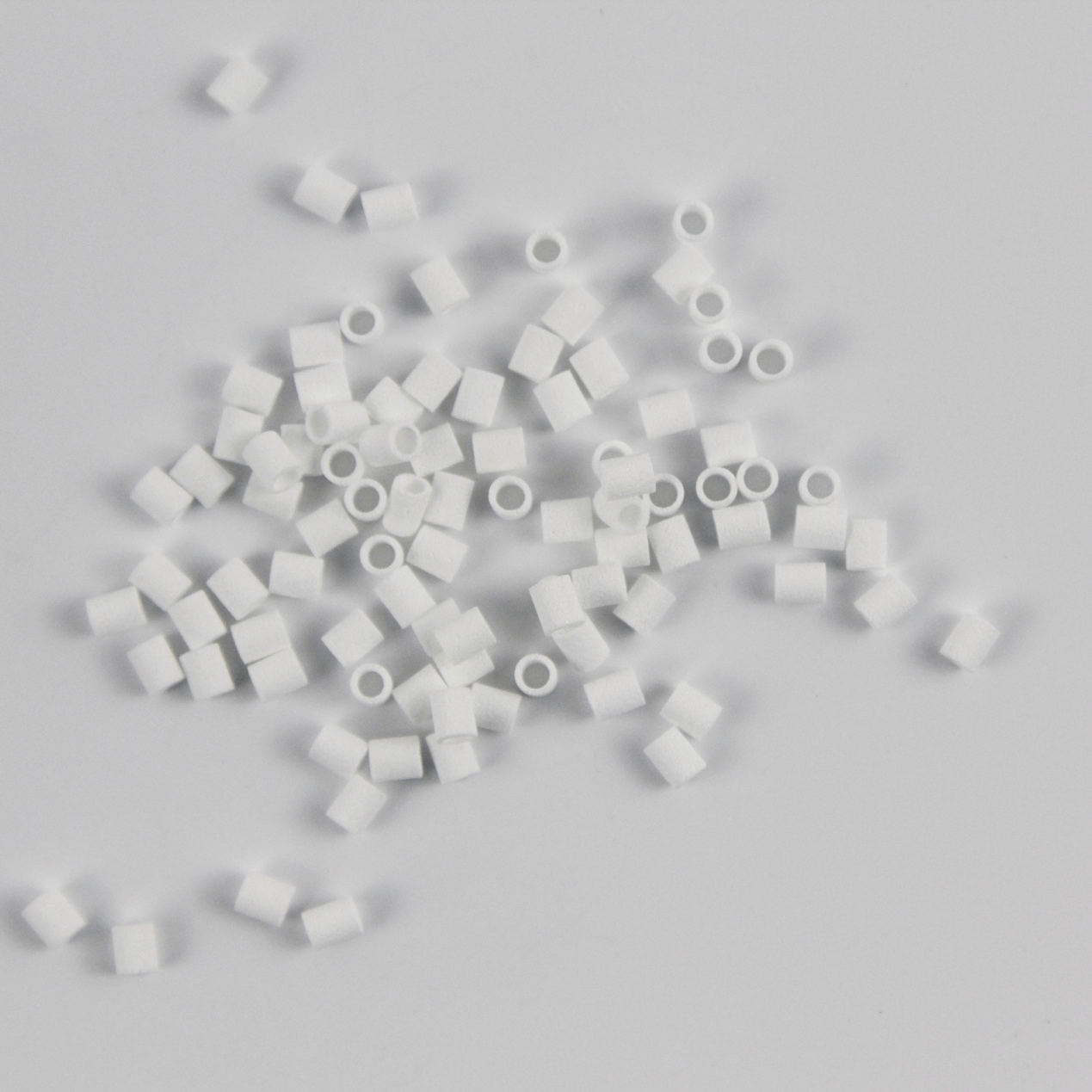

● The filter cotton has different specifications and models for different placement machines. Oil and moisture will be generated in the compressed air to filter some foreign bodies and impurities. So as not to affect the service life of the equipment, resulting in low production efficiency.

● Dust in the air falls on the rotating parts of the machine, which will accelerate the wear of the rotating parts, reduce the accuracy and life of the machine. Dust can be diffused in the workshop, and it can also reduce visibility, affect the field of vision, hinder operation, reduce labor productivity, and even Will cause accidents. Dust discharged into the atmosphere will cause air pollution.

● The dust in the air will also reduce the visibility of the atmosphere, promote the formation of smog, and affect the transmission of solar radiation energy

In summary, filter cotton has its indispensable position, because many industrial production must be carried out in a relatively clean space, such as surface treatment, paint coating, spraying, precision electronics, optical electronics, biological manufacturing, food Production, air cooling, etc., these environments require flowing air, but no dust, so filter cotton is needed to filter out the dust and only allow clean air to circulate in a relatively closed space, so as to meet the needs of production and operation.

Post time: Feb-11-2022