Surface Mount Technology (SMT) is at the forefront of modern electronics assembly. The ability to rapidly and accurately place components onto circuit boards is crucial in today's fast-paced electronics industry. At the heart of this technology are various components, each serving its unique purpose. Let's delve into the categorization and roles of these pivotal elements.

1. Motion and Accuracy: Ensuring Precision Every Step of the Way

The SMT machine's motor provides the mechanical drive required for precise movement. Whether it's the rapid positioning of a placement head or the smooth sliding of feeders, the motor ensures speed and accuracy in synchronization.

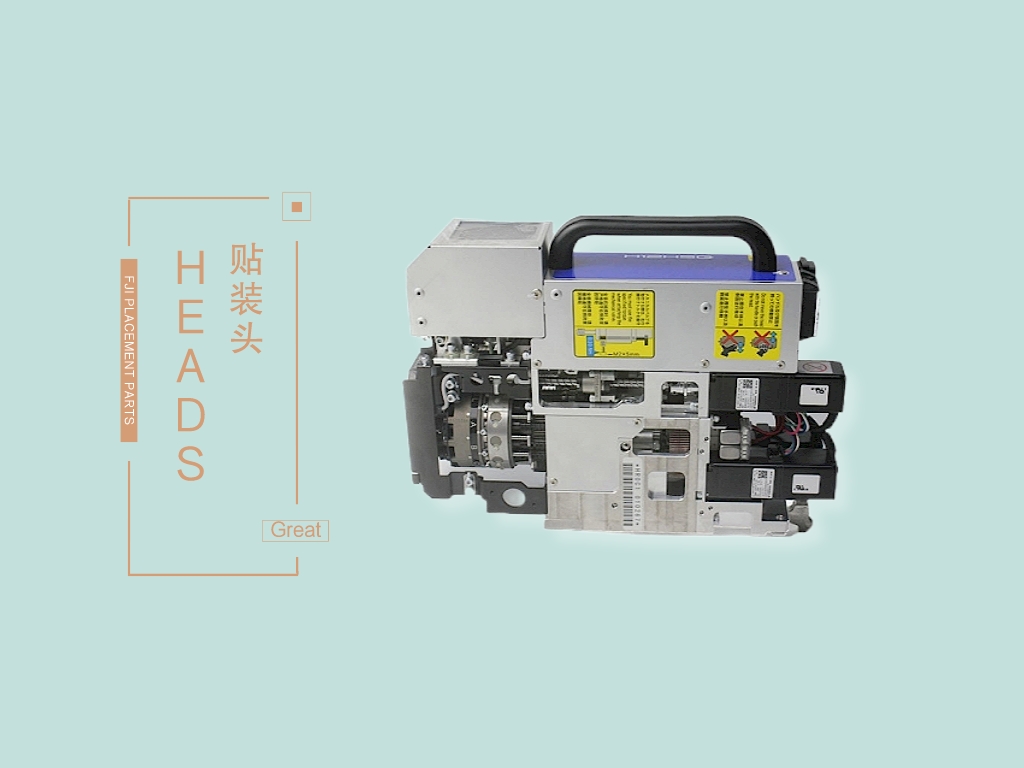

This component is responsible for picking up the electronic components and accurately placing them on the PCB. It demands precision, and its smooth operation is paramount for a defect-free assembly.

This device translates rotational motion to linear motion with little friction, allowing for precise control and movement, especially in placement operations.

Just as a belt drives a pulley, the SMT belt is fundamental in maintaining the synchronization of various moving parts, ensuring a smooth workflow.

2. Component Management: Delivering Consistency and Efficiency

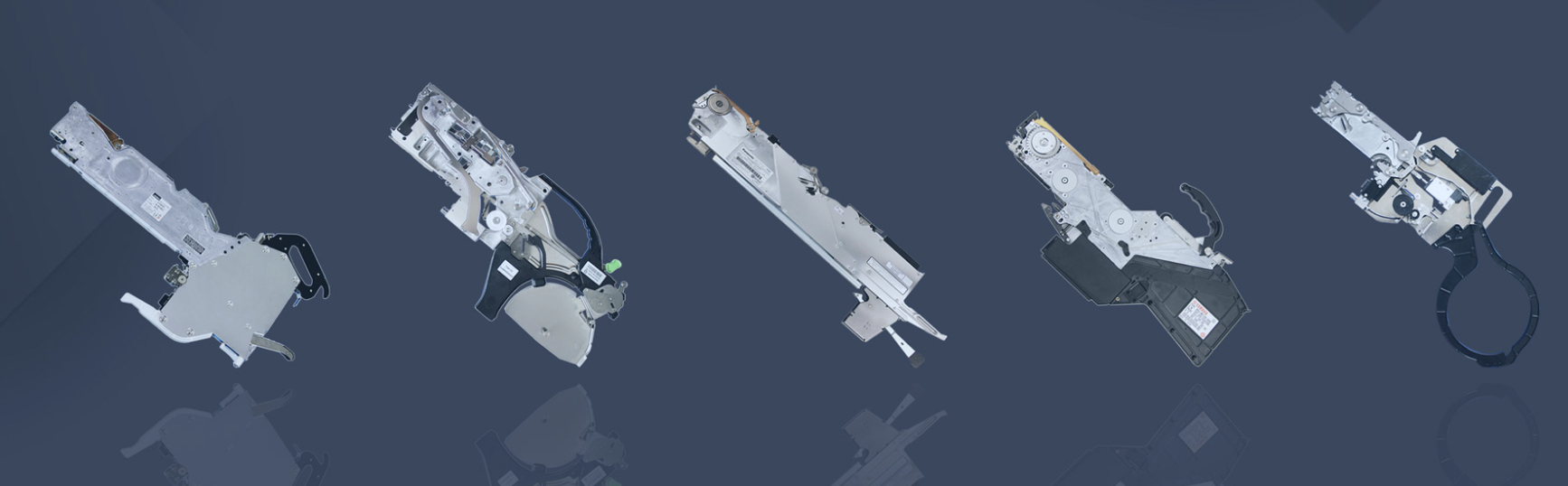

The SMT feeder plays a critical role by ensuring that components are continuously supplied to the placement head. It's like the conveyor belt of the SMT world, delivering each component just in time for placement.

3. Connectivity and Command: The Communication Champions

Acting as the interpreter, the servo driver ensures seamless communication between software and machine components, translating commands into actions.

The nerve center of operations, these boards process signals and oversee the harmonious collaboration of all machine parts.

4.Maintaining Purity and Streamlining Flow: The Essence of Flawlessness

Operating in a clean environment is essential. The SMT filter ensures that any contaminants are removed, preventing potential defects and ensuring the longevity of both the machine and the final product.

Tasked with regulating flow, this valve ensures a proper vacuum is created, which is essential for picking up components or ensuring an airtight seal during specific processes.

5. Detection and Feedback: The Senses of SMT Machines

Sensors in SMT machines detect various parameters like component presence, positioning accuracy, and more. They provide real-time feedback, ensuring that any anomalies are detected and addressed promptly.

These are the lifelines that carry signals between different parts of the machine. From powering motors to transmitting data between boards and sensors, cables are the silent carriers of essential information.

In the complex world of SMT assembly, it's evident that every piece, from the Ball Screw to the SMT Camera, is crucial for optimal performance. When seeking peak production efficiency, understanding and maintaining these components is paramount. Always prioritize quality, especially when sourcing parts, to ensure your SMT machine operates at its best.

www.rhsmt.com

info@rhsmt.com

Post time: Oct-27-2023