KE-2070L

High-speed flexible chip shooter

High reliability platform combined with high speed.

JUKI, pioneer of “modular” introduces

Ultra flexible mounters for today’s advanced production requirements

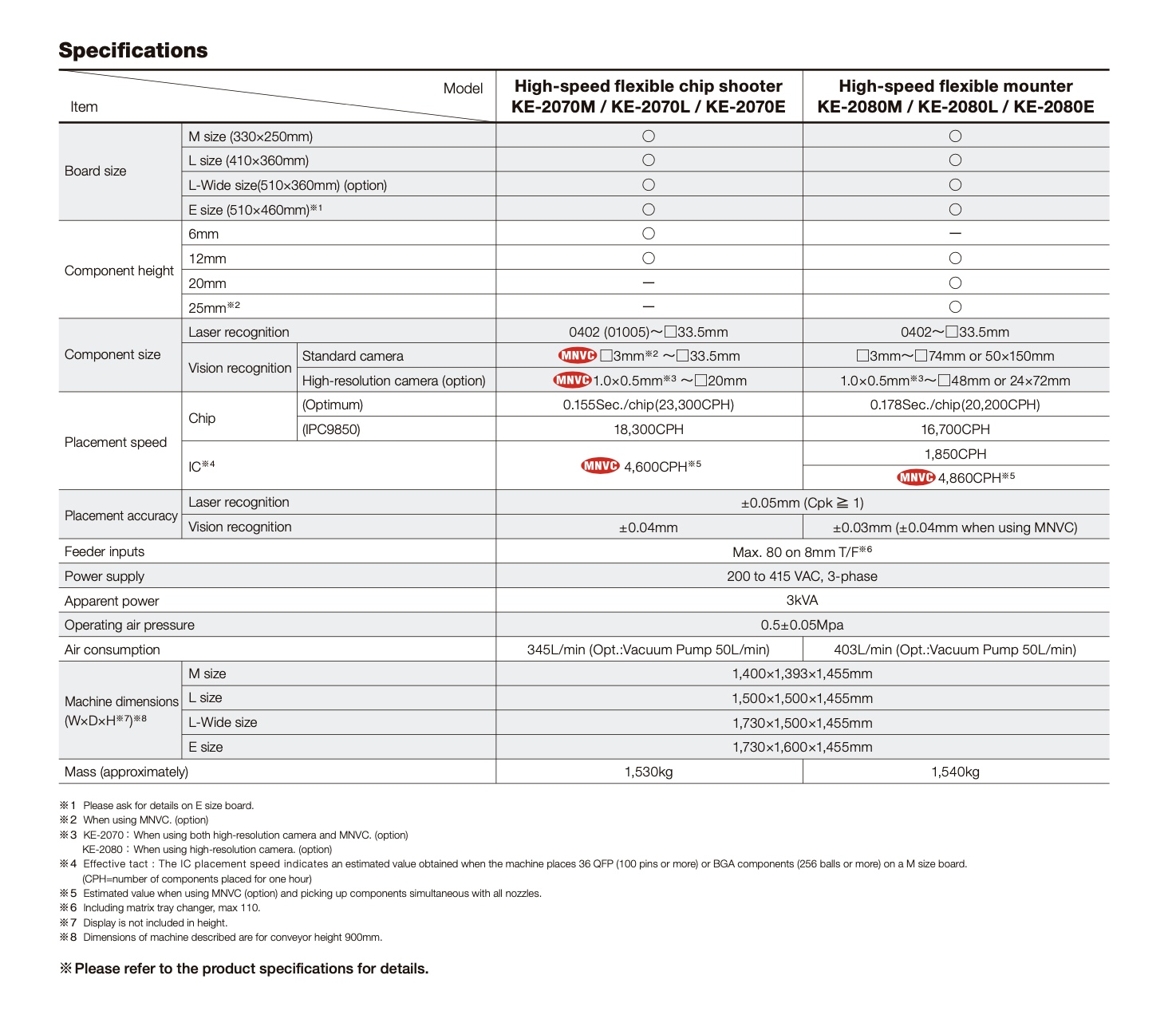

18,300 CPH

0402 to 33.5mm

A 23% improvement in throughput in the same footprint

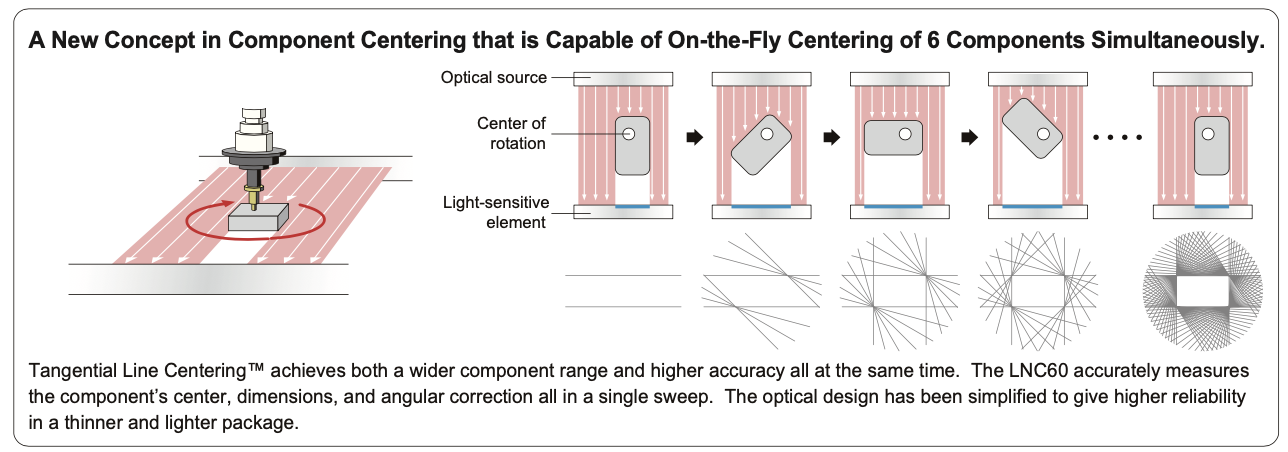

The new LNC60 laser head is capable of picking and centering 6 components simultaneously. It can reach speeds of up to 18,300 CPH (IPC-9850), a 23% improvement over the previous generation.

A variety of different nozzles can be attached at the same time, decreasing the nozzle change time. With the optional MNVC (multi-nozzle vision centering), the throughput for high accuracy devices is increased a remarkable 40%.

And all of these features are found in a remarkably compact machine for unparalleled productivity.

Unrivaled placement range from 0402 (01005) to 33.5mm square components

The LNC60 brings a new concept in laser centering to the market. This sensor has the unique ability to center components from 0402 (01005) to 33.5mm square parts. From ultra-small, ultra-thin, chip-shaped parts to small QFP, CSP, BGA, a wide range of parts can be mounted by the laser recognition system at high-speed and with high-accuracy.

Splicing tape feeder ATF is featuring tape splicing for easy component replenishment during production. Like previous generations, the ATF is fully backwards compatible with all KE and FX series models.

Standard Nozzles and Special nozzle

We provided original new/ Copy new standard nozzles (500-509), and can design and make the special nozzles.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top