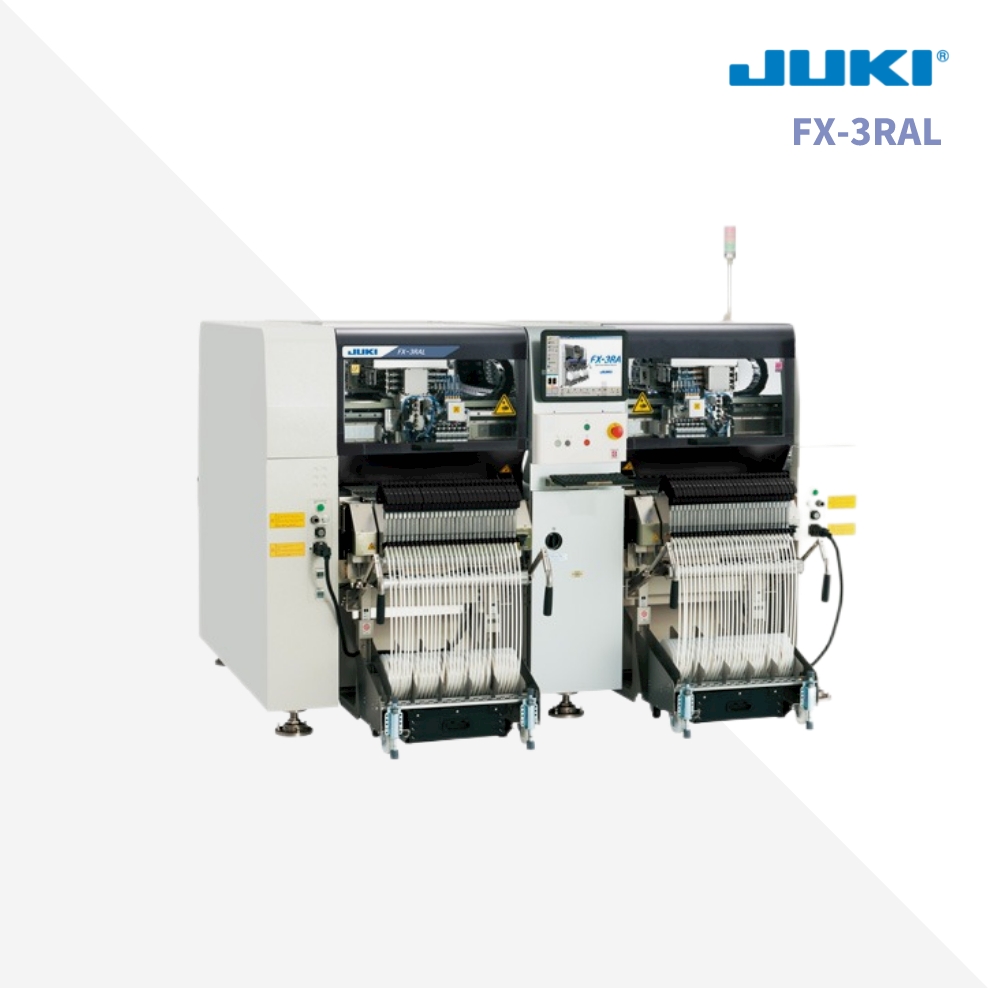

JX-300LED

LED Mounter

For Lighting Applications, LCD Backlights and Large LED Boards

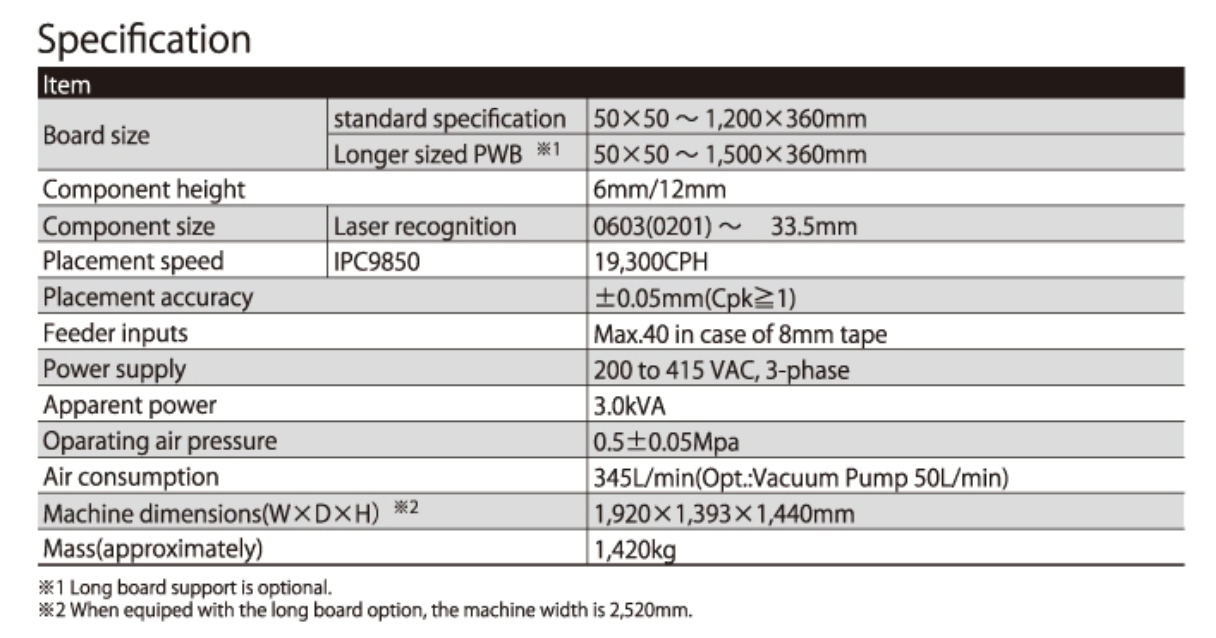

19,300 CPH

0603(0201) to 33.5mm

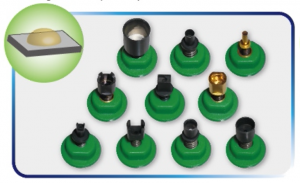

Wide variety of special nozzles for LEDs

JUKI has tremendous experience in LED placement and designs nozzles specifically for LEDs. Contact us for more information.

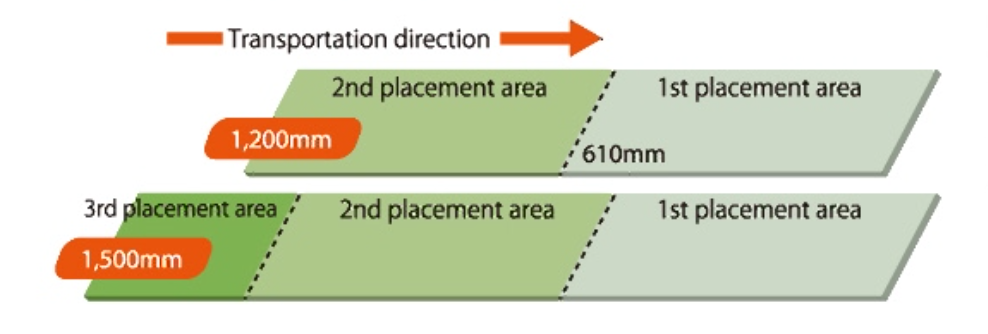

Supports ultra-long boards up to 1,500mm

Productivity is improved by optimizing placement distribution over placement areas and shortening the clamping time. A new high-speed clamping system reduces the transport time for long and ultra-long boards.

Unique features for flexibility

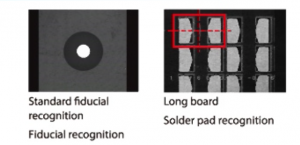

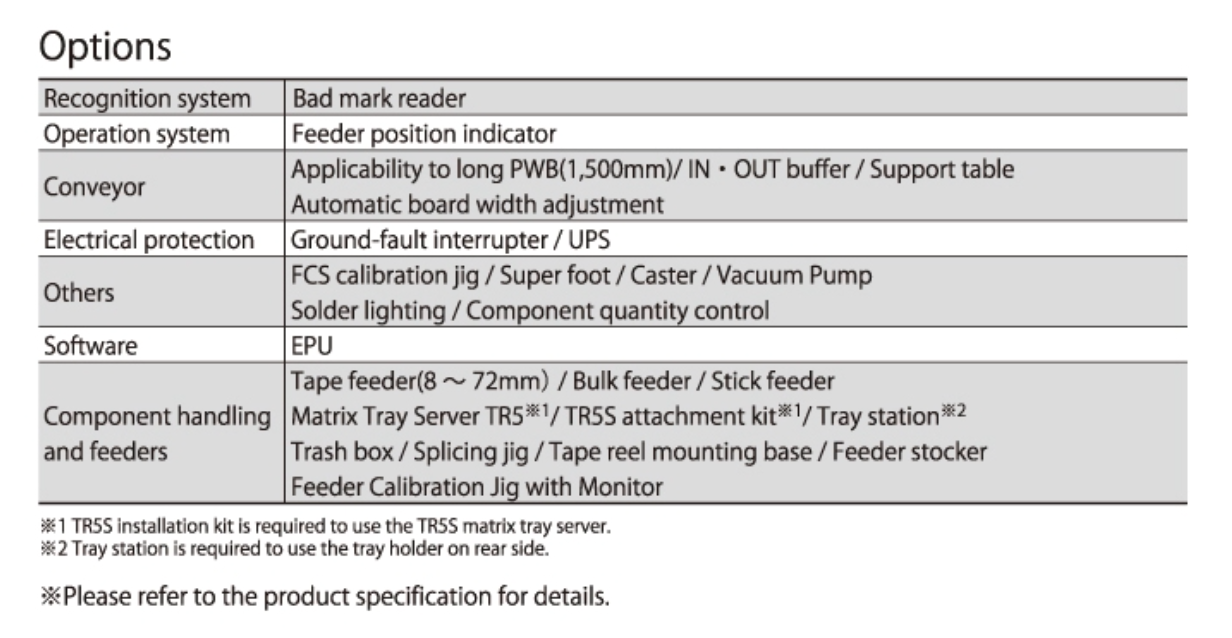

Accurate placement even without fiducial marks.Using JUKI lighting and fiducial recognition technology, the JX-300LED can use solder pads as fiducials. Remaining part quantity management - To prevent variations of LED brightness due to lot differences, the number of parts remaining in the feeders is checked prior to starting production. If there are not enough parts to complete the board using the loaded feeders, an alarm is displayed.

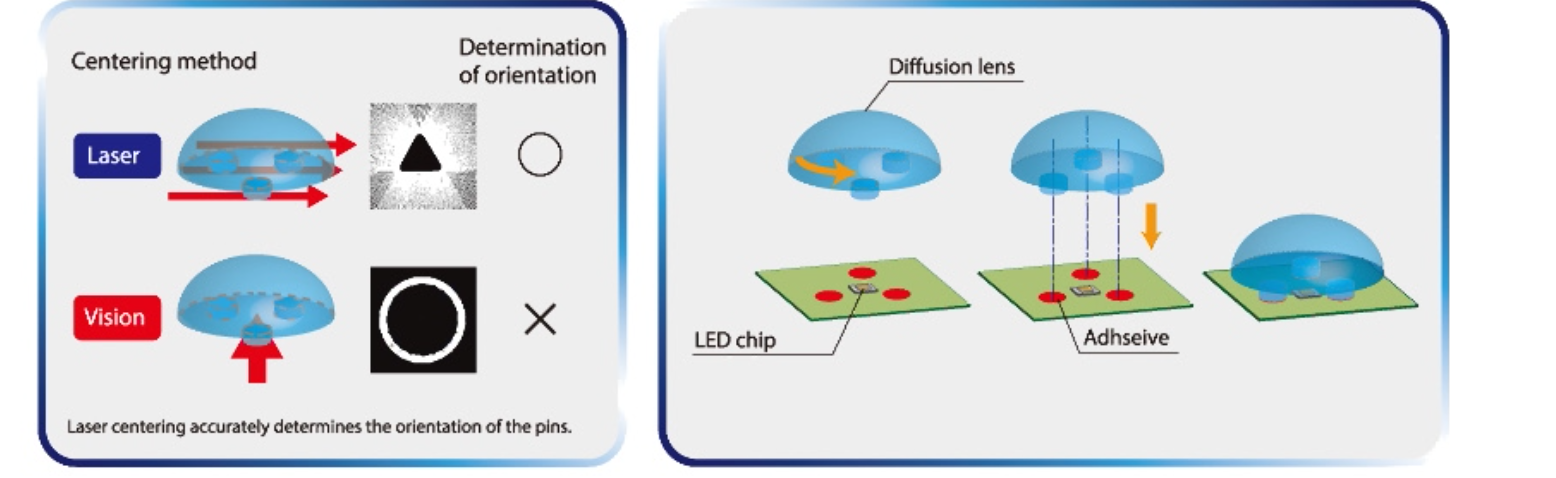

JUKI laser centering for high speed, high accuracy placement

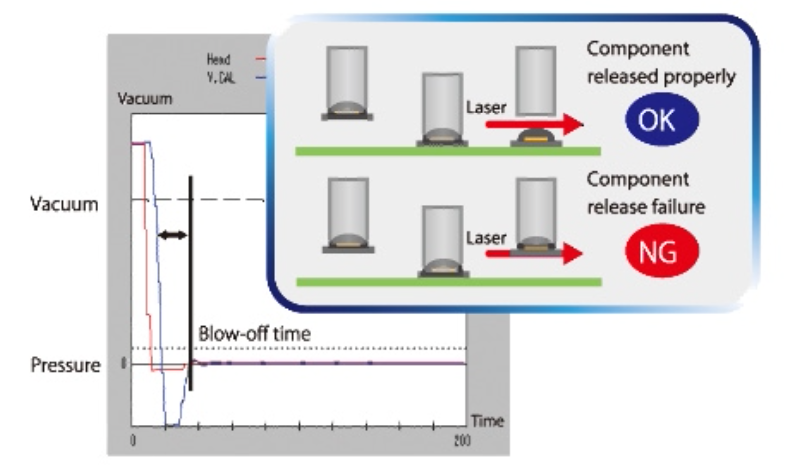

Improved placement quality -Component release is monitored by the laser sensor to ensure components are not picked up after placement.

Blow-off can be set for components with sticky top surfaces.

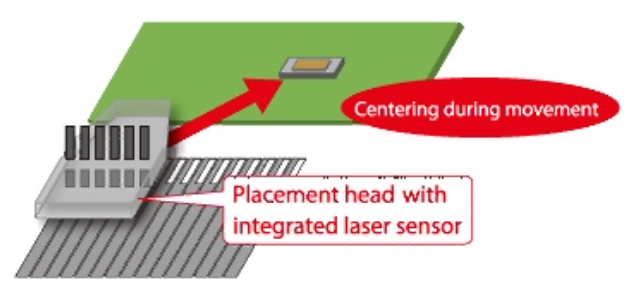

The integrated laser centering allows the head to move directly from the pick position to the placement position.

Component centering is done on-the-fly between the pick position and placement location by the integrated laser sensor.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top