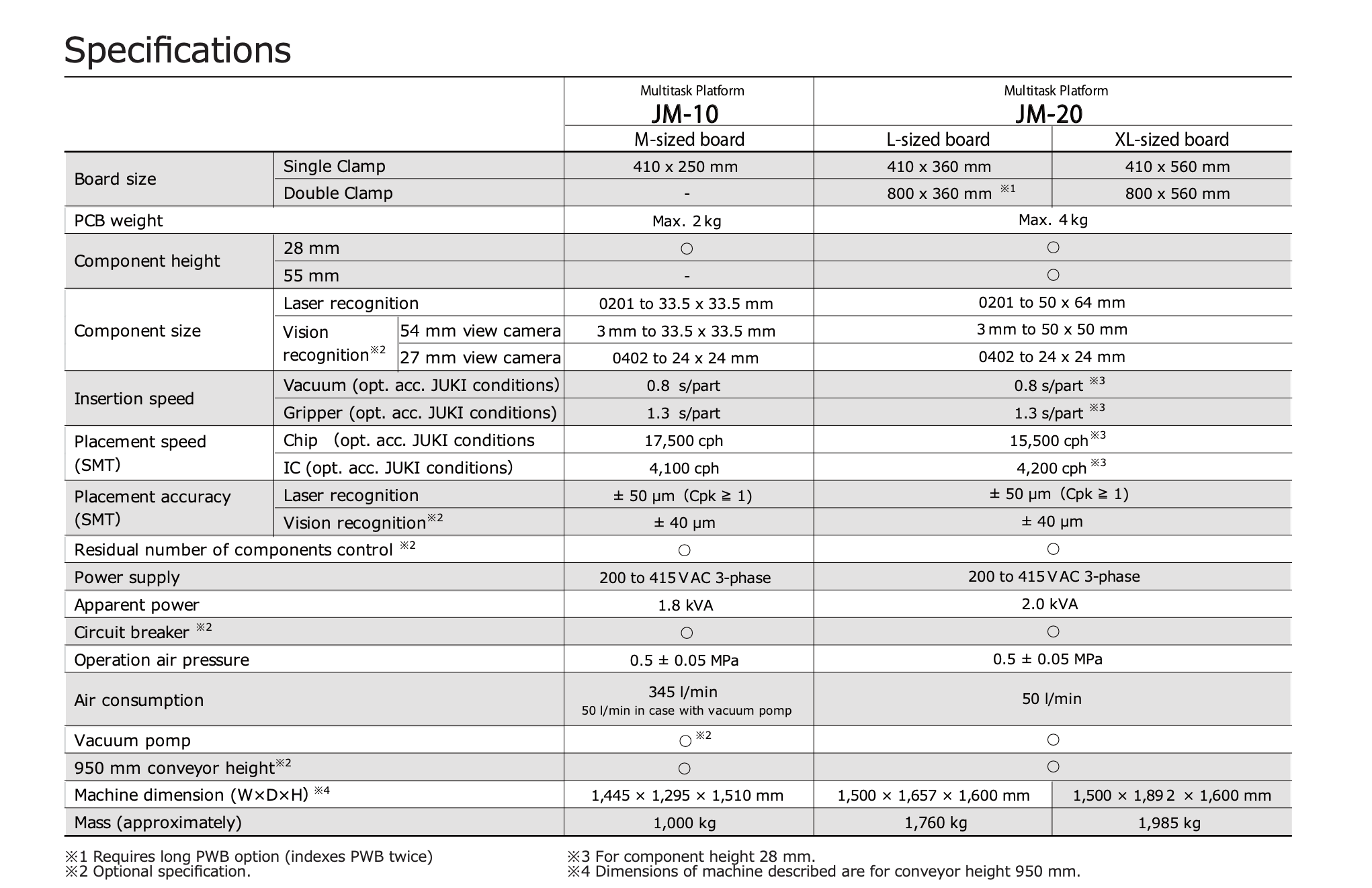

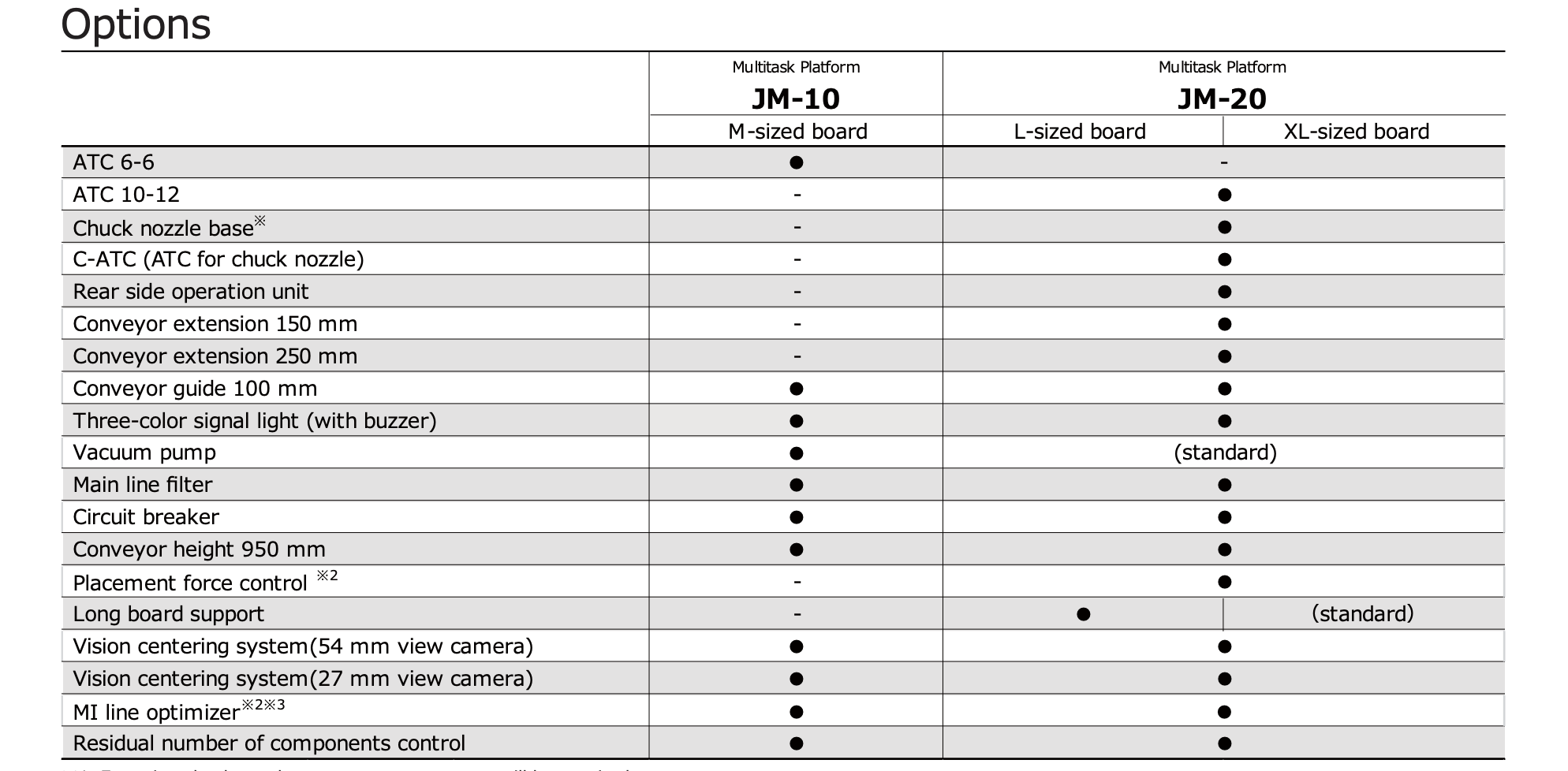

JM-20

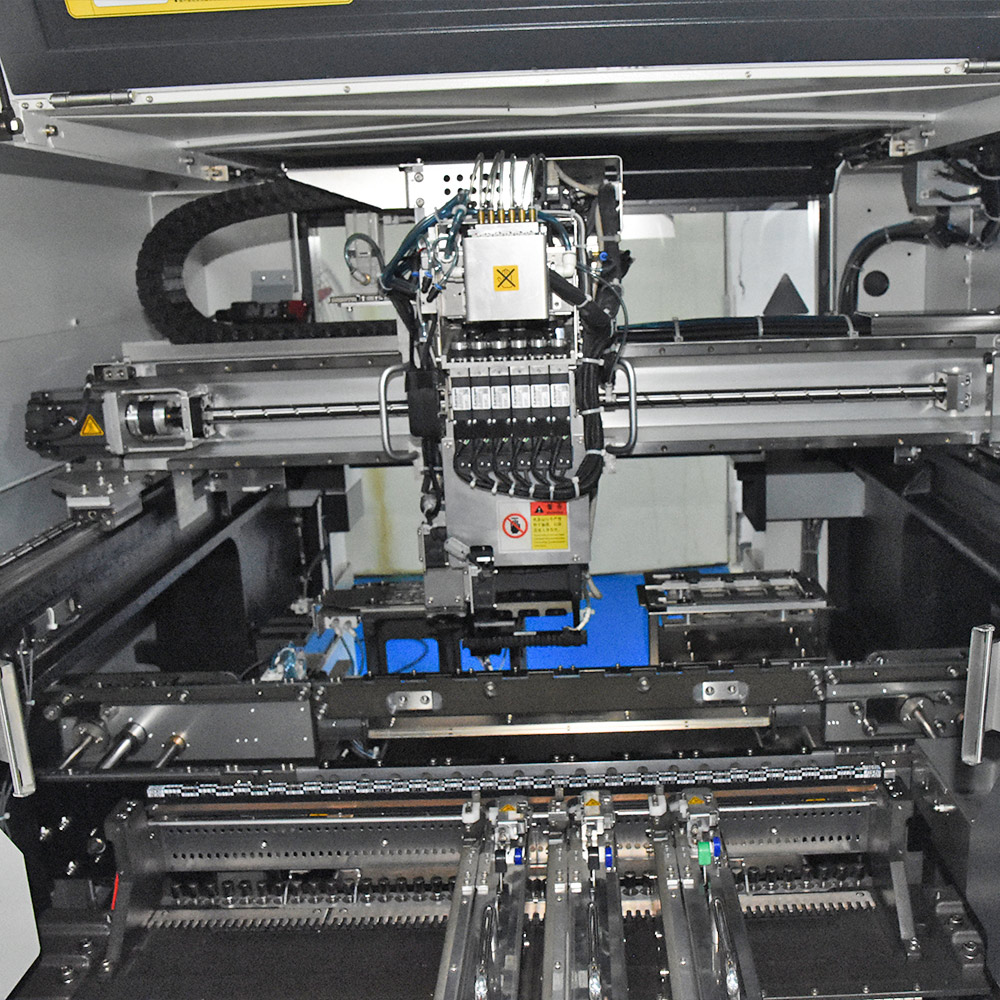

Multitask Platform, SMD mounter

Higher quality and labor savings by automating manual insertion,

Advanced model for larger/heavier components and larger boards

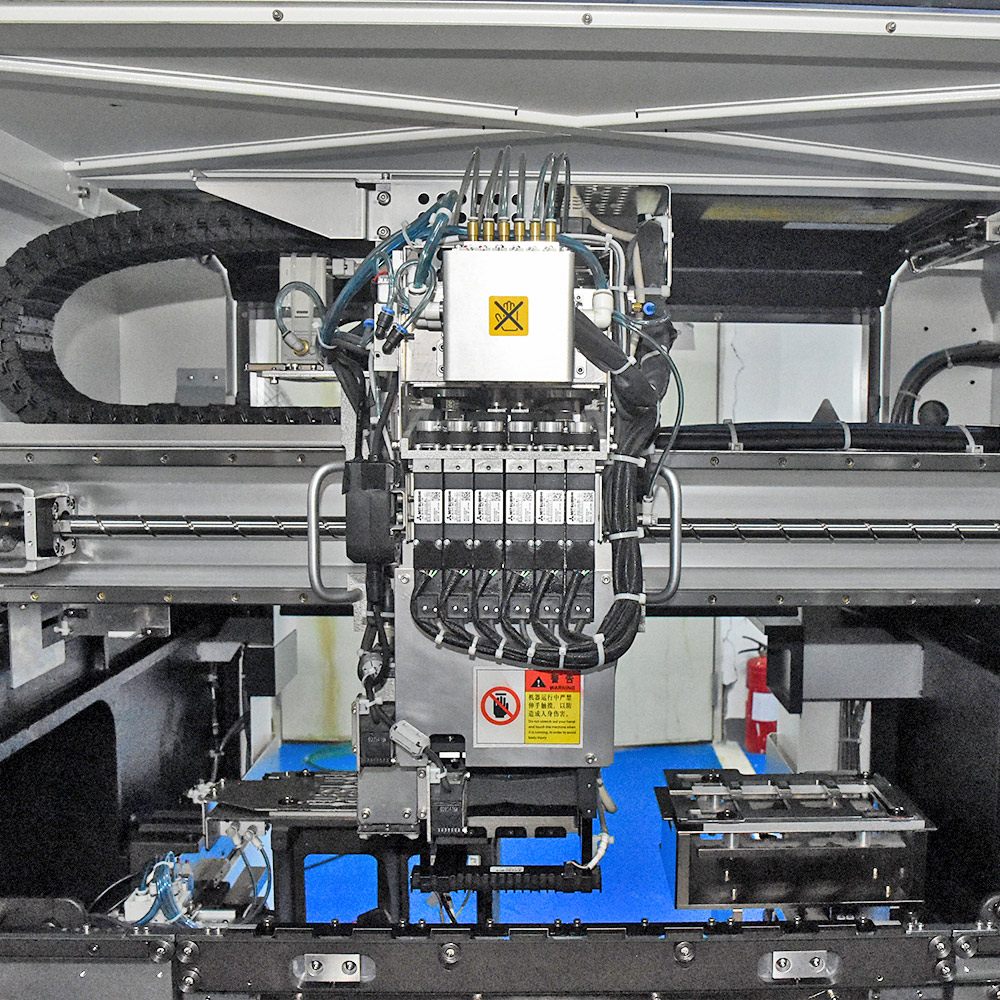

15,500 CPH

0201 to 50x64mm

Feature

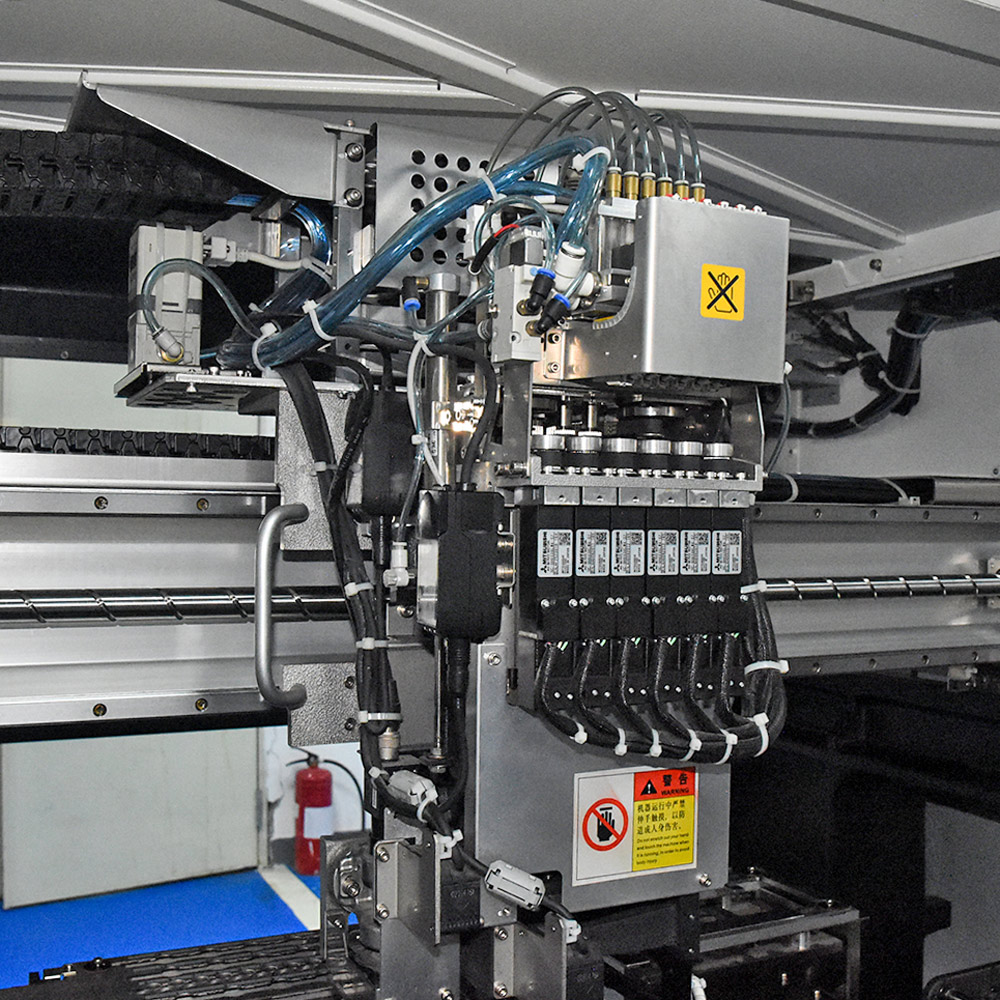

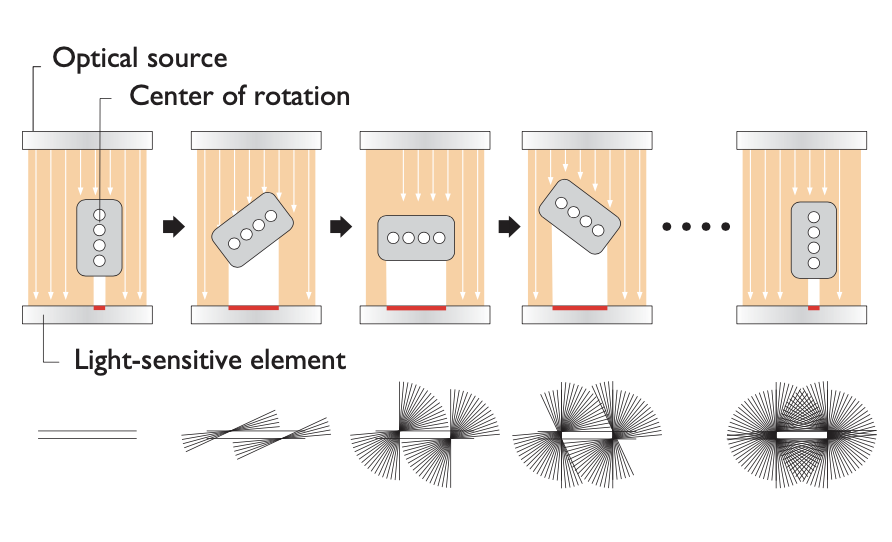

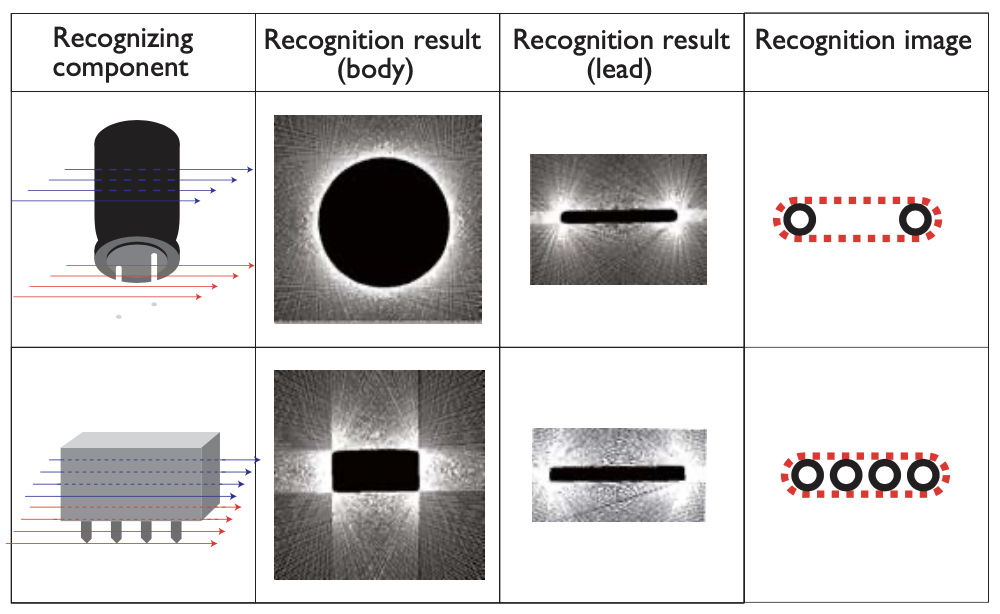

Laser sensor for lead detection

Components are rotated 360 degrees in the laser. The entire outline of the component is measured accurately by a high resolution CCD sensor. The exact component position and angle are obtained in a fraction of a second without a side trip to a camera.After measuring the component body, the lead tips are measured to ensure accurate insertion.

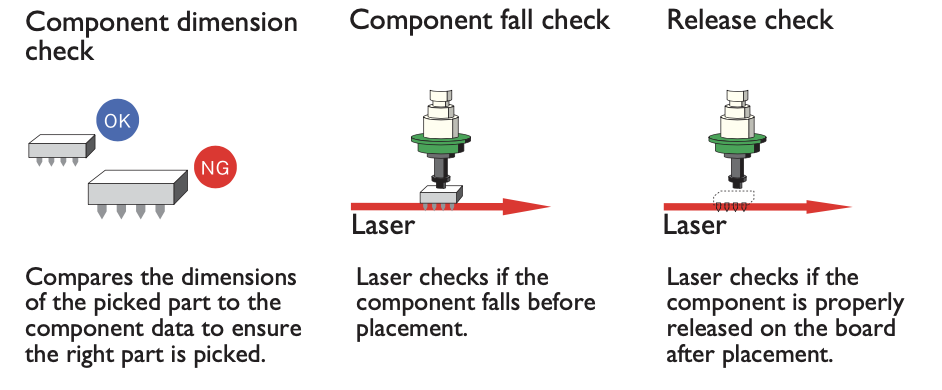

Improved placement quality with component detection function.

Laser detects component presence from pick to placement, reducing defects.

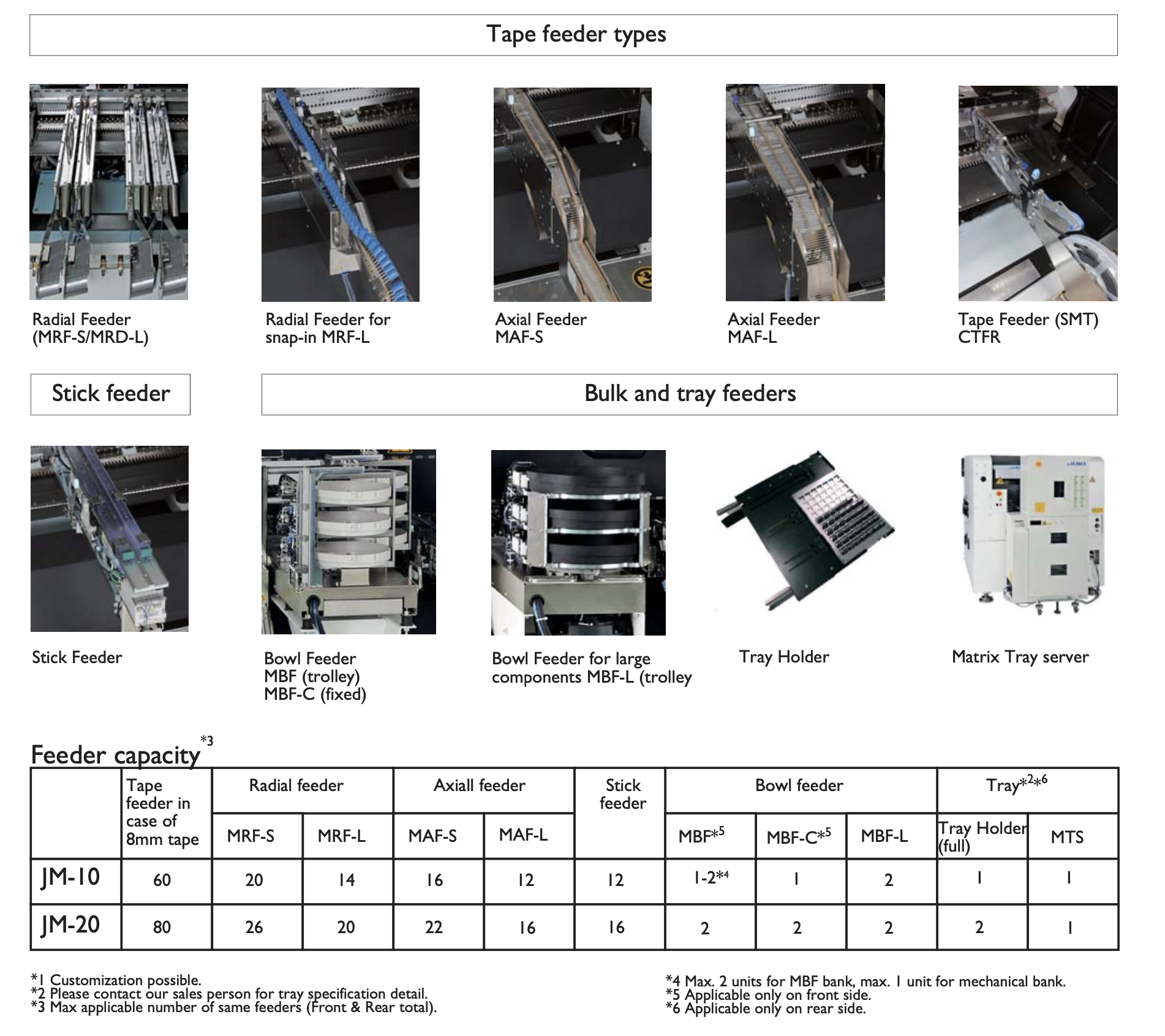

Wide variety of feeder types

Feeders for tape, stick, radial, axial, tray, and bulk components. A wide variety of custom feeders is also available.

Nozzle types

We specialize in the design and production of various JUKI special nozzles, which can be designed according to the drawings of components provided by you, including suction nozzles, chuck nozzles, LED nozzles, etc.

Why Choose US?

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top