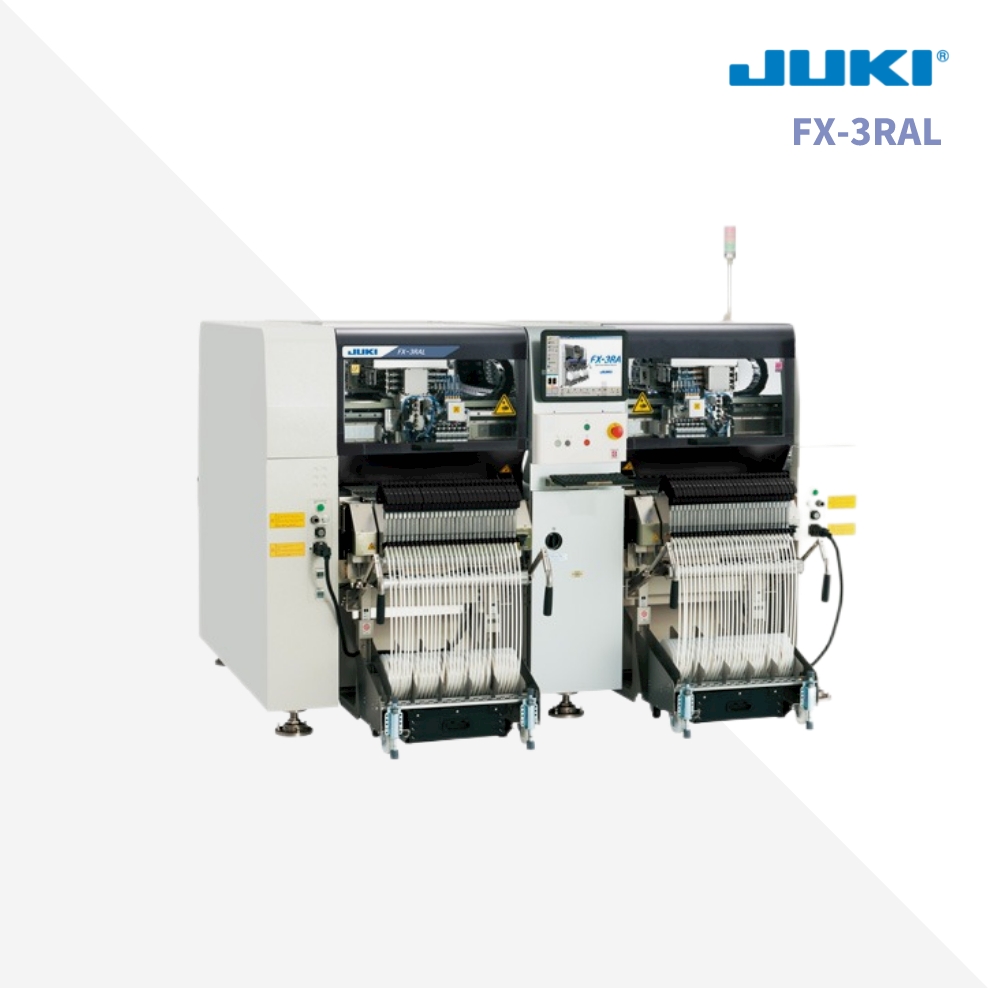

FX-3RAL

High-speed Modular Placement

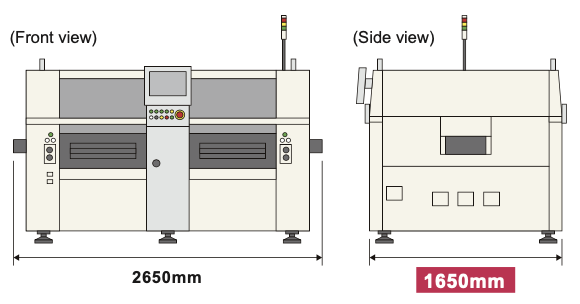

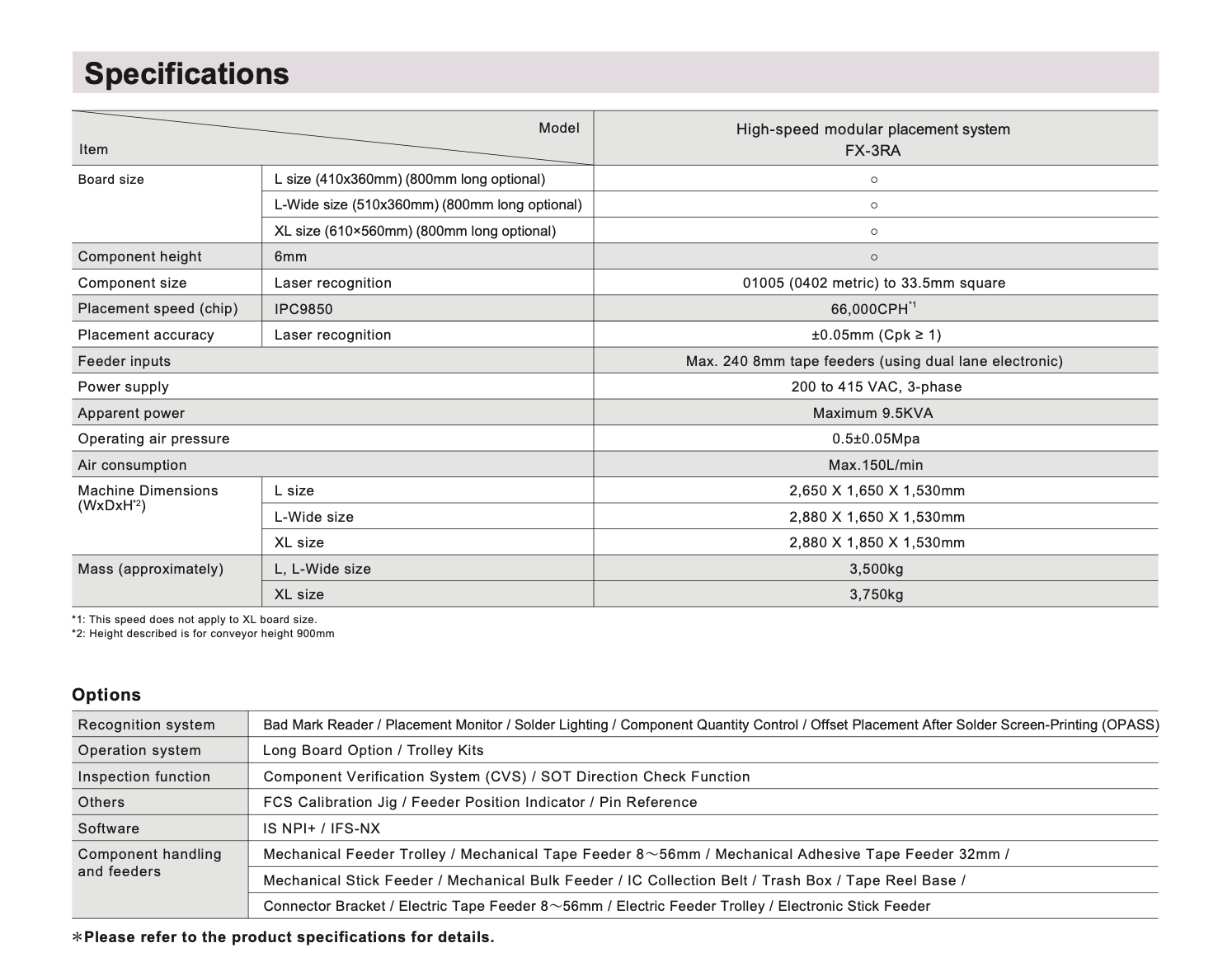

From the pioneer of the modular assembly line comes the latest technology in high volume production at the lowest cost of ownership. Offering an interchangeable electronic and mechanical feeder solution combined with a new 22” x 32” maximum board size, the continuously evolving FX-3RA offers the utmost in flexibility, reliability, and ease of use for both high speed and high mix manufacturing environments.

66,000 CPH

0402 to 33.5X33.5mm

User-friendly Operation

15-inch Touch-panel Color LCD Display

〇 Easy teaching using touch screen while looking at the component

〇 The graphical user interface is designed for simple operation

〇 The language can be changed at any time

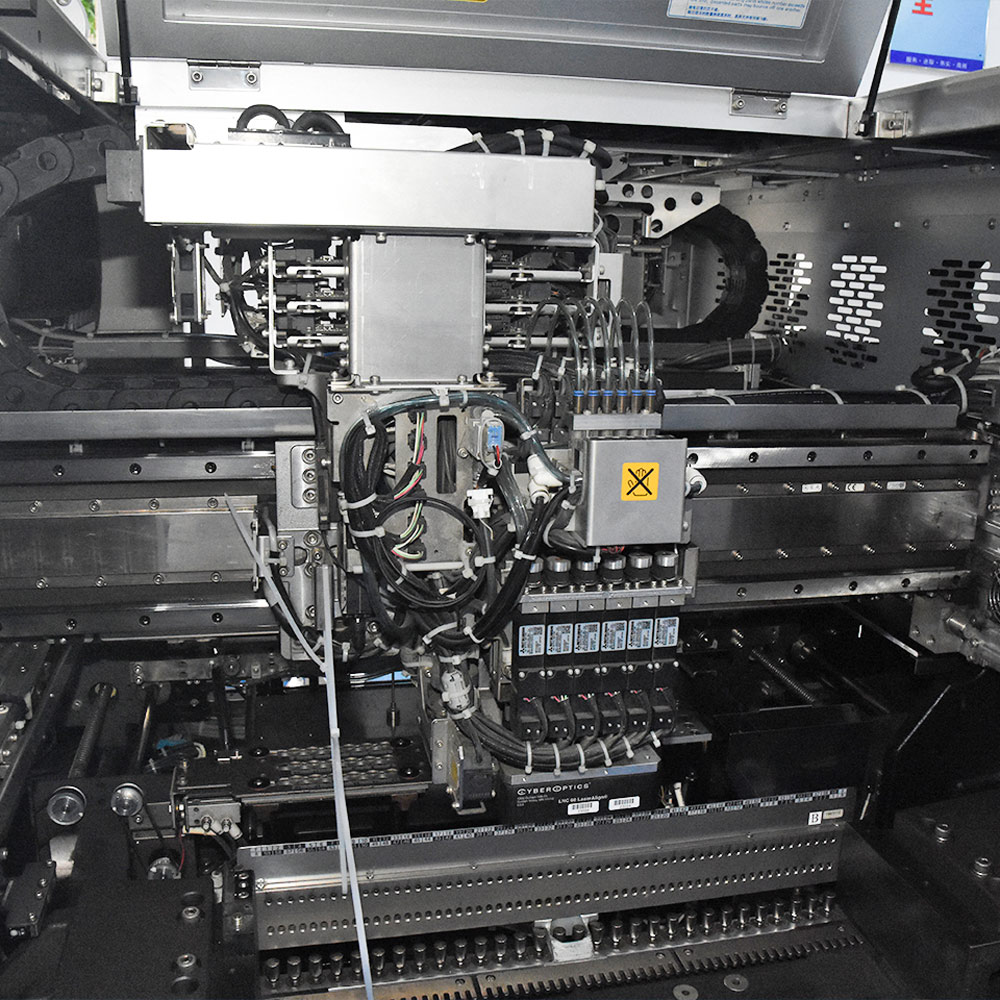

High-speed Technology

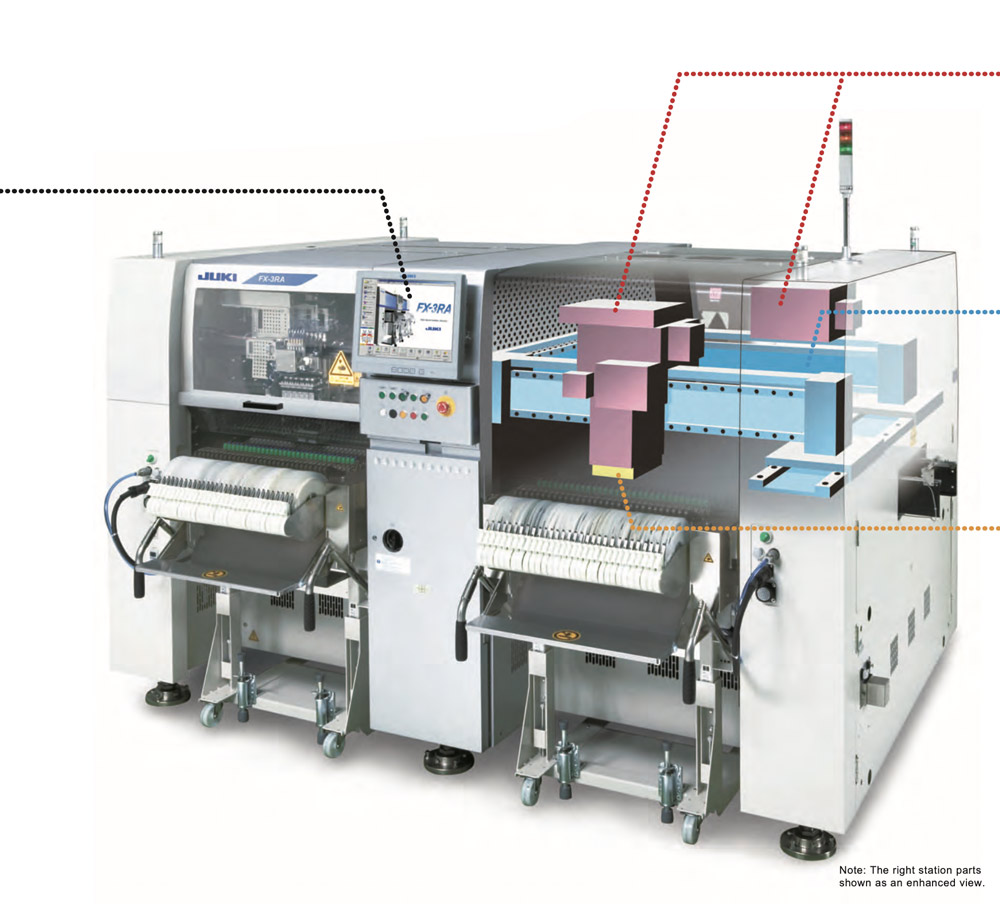

1. 15-inch Two Stations - 4 Beams

The FX-3RA can reach placement rates of up to 66,000cph (IPC9850) using four independent beams, each with a 6 nozzle placement head at two placement stations.

2. X-Y Linear Servomotors

Linear servomotors are used for all of the X-Y axes. Best-in- class performance is achieved by using high-accuracy, incredibly responsive cutting-edge axis control technology.

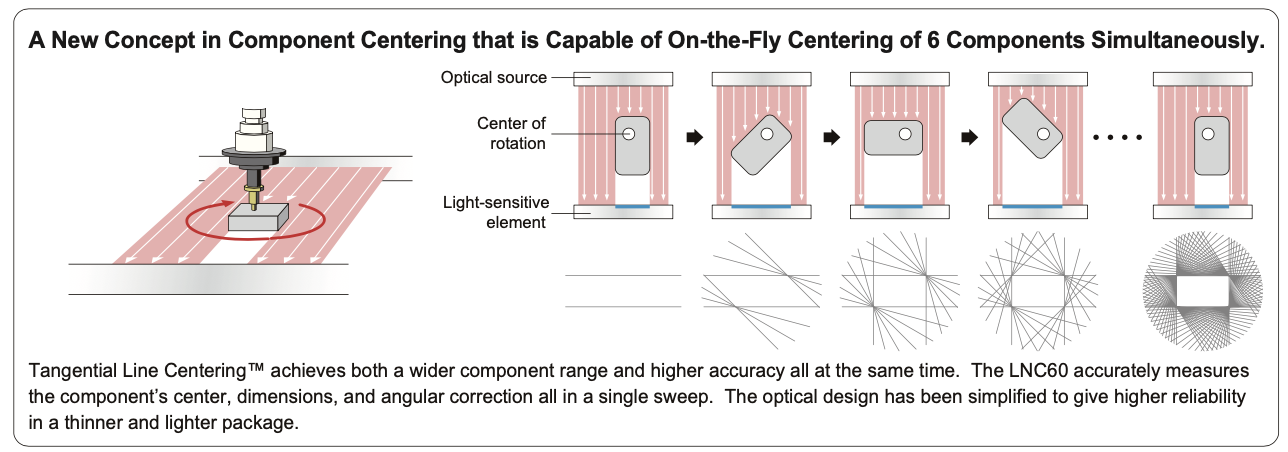

3. On-the-fly Simultaneous Centering using the 6-nozzle Multi-laser Head

Up to six components can be picked and then centered simultaneously using high-resolution on-the-fly laser centering for high-speed placement.

Independent Z / θ control

Each nozzle has independent Z and θ motors for high reliability and high accuracy. Precise control of each nozzle is possible without affecting components on other nozzles

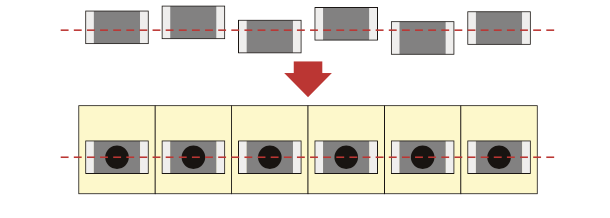

Chip placement speed is greatly improved

Simultaneous picking and on-the-fly parallel recognition with six nozzles are achieved by using the high resolution LNC60 laser sensor.

Unrivaled placement range from 01005 (0402 metric) to 33.5mm square components

The LNC60 brings a new concept in laser centering to the market. This sensor has the unique ability to center components from 01005 (0402 metric) to 33.5mm square parts. From ultra-small, ultra-thin, chip-shaped parts to small QFP, CSP, BGA, a wide range of parts can be mounted by the laser recognition system at high-speed and with high-accuracy.

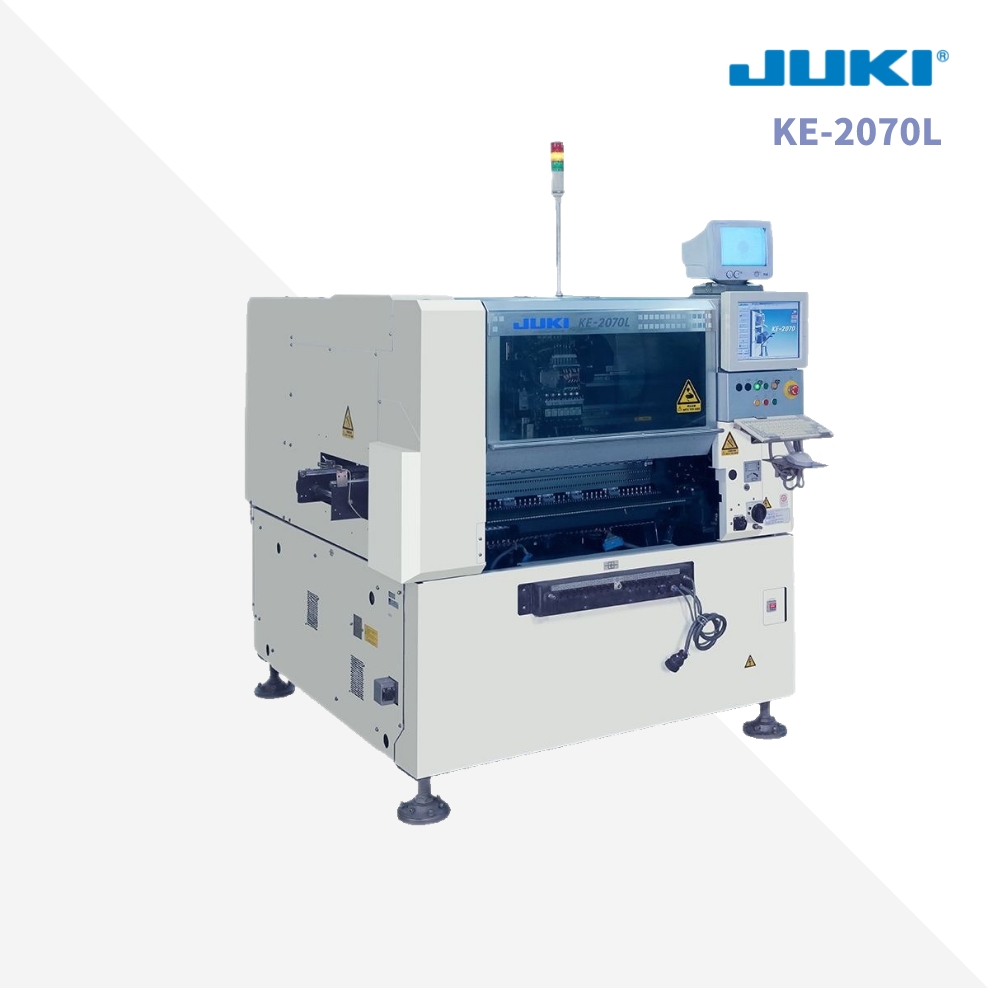

The motor driven electronic feeder tape feeder is designed for fast, smooth and reliable component feeding.

A new electronic double tape feeder allows up to 240 different components to be loaded, the biggest capacity in the industry. It is ideal for low volume/high mix environments where more files could be clustered into one setup to dramatically reduce change-over time.

Simple Switching of the Feed Pitch

Simply press a button to change the feed pitch.

Status is displayed with Seven Segment LED

Before production, electronic feeders communicate with the production program to verify the type of feeder and feeder pitch. An LED flashes if there is a discrepancy. The LED display also alerts the operator to running out of components and incorrect feeder position. During machine operation the LED display shows its feeder position.

Automatic Correction of Pick Position

The variance of the position from the center of each component is detected by the machine head when centering. This information is transmitted to each electronic feeder which automatically adjusts feeding for more stable pick position and for more chance of simultaneous pick.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top