Hot sale Factory Cleaning Soda Machine Nozzles - SOLDER MIXER – NSTAR-600 – RHSMT Detail:

Function

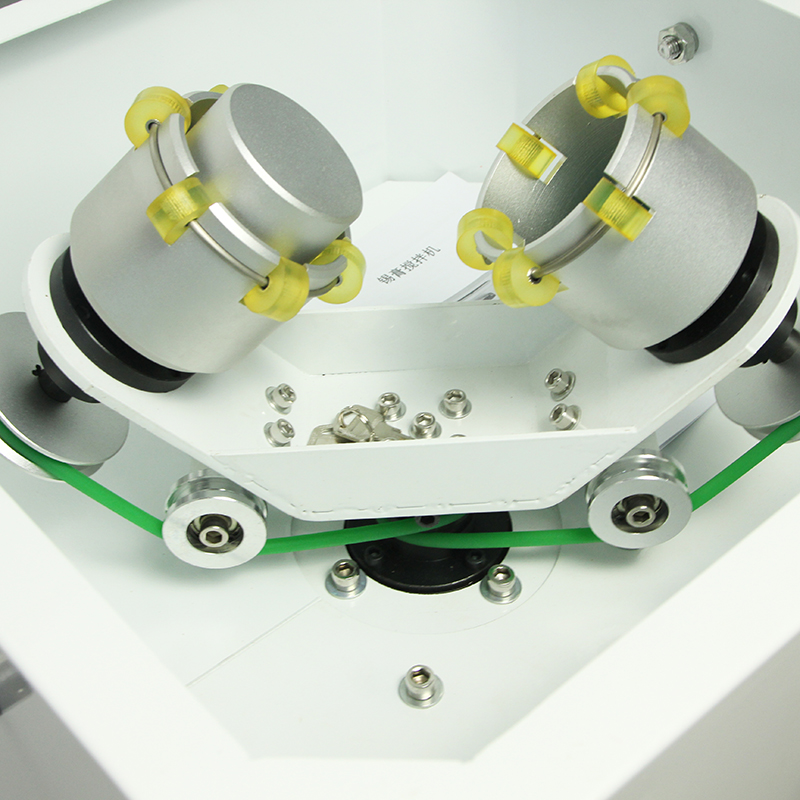

1). The machine is fully automatic solder paste mixer that features simple operation and excellent mixing performance. The operator doesn’t need to open the solder paste bottle during the mixing process so that the solder paste will not contact the air and will not get oxidized.

2). Mixing mechanism: The mixing is done by both revolution and rotation of a motor installed inside the machine. The operator can take out the cold-stored solder paste bottle directly from refrigerator and start to use the machine to mix the paste. The operator doesn’t need to wait for the solder paste to reach the same temperature of the working environment. The solder paste will be efficiently mixed within short time and be ready for use in the SMT printing. The fast and automatic mixing makes simple and standard SMT printing possible so that the overall SMT productivity can get improved. Besides, the old and the new solder paste can be mixed together and can still achieve satisfactory Q activity of solder paste. The mixing time can be set and be fixed for each operation.

Power Supply

Power supply: AC220V.50/60HZ; 45W

Machine specification

|

Machine Net Weight |

32kg |

|

Machine Dimension |

(L) 410 * (W) 410 * (H) 490mm |

|

Power |

40 W, AC220V.50/60HZ |

|

Motor |

40W AC motor |

|

Mixing Capacity |

Ideal for 1 bottle of 500grams or two bottles of 500grams each. |

|

Motor Rotation Speed |

1350 RPM |

|

Revolution Speed |

500 RPM |

|

Application |

Applicable for any common size of paste bottles |

|

Mixing Time Adjustment |

Time adjustable with range of 0 ~ 9.9 minutes |

|

Warranty |

1 year |

|

Features |

Reliable and stable |

|

|

No noise during working |

|

|

Special 45 degree tilting design, resulting in no contamination inside the bottle lid |

Panel buttons and Operation

1). START button:Once the button is pressed, the motor will start to rotate. (The machine lid much be closed before pressing the START button)。

2). STOP button:Once the button is pressed, the rotation will be stopped. The rotation will not stop until the set mixing time has reached. If you want to stop the rotation earlier than the set mixing time, press this button.

3). Mixing time setting buttons

There are four buttons for setting mixing time. The two buttons on the left side are used to adjust up and down the value of minutes, while the two buttons on the right are used to adjust up and down the value of seconds. The machine will stop rotation automatically when set mixing time is reached. The set time will be saved by the machine automatically and the operator doesn’t need to set again next time.

Operation Procedure

1). Open the top lid

2). Open the clamp locker

3). Put the solder paste bottle that need to be mixed into the clamp. If two bottles need to be mixed at the same time, put each bottle into the left and the right clamp. If there is only bottle solder paste, put the bottle into one clamp, and put one balance weight (provided with the machine) into the other clamp. The balance weight has two kinds: 500grams and 300grams for choice.

4). Lock the clamp

5). Close the top lid

6). Press START button

Safety Instructions

1). Don’t put the machine at damp and wet places. Keep the machine surface clean.

2). Take care when moving the machine. The machine need to be placed at a even and clean ground.

3). When putting solder paste bottle, the operator should not forget to lock the clamp to avoid accident.

4). Just press the START button when need to mix the solder paste. The mixing time doesn’t need to be reset next time if the mixing time is same.

5). Don’t put heavy goods on the machine top lid.

6). Don’t open the top lid and take out the solder paste bottle until the motor has completely stopped rotation in order to avoid accident.

7). The bearing is installed inside and doesn’t need to be oiled very often.

Detail

Product detail pictures:

Related Product Guide:

To become the stage of realizing dreams of our employees! To build a happier, much more united and far more professional team! To reach a mutual profit of our clients, suppliers, the society and ourselves for Hot sale Factory Cleaning Soda Machine Nozzles - SOLDER MIXER – NSTAR-600 – RHSMT , The product will supply to all over the world, such as: India , Jakarta , Sheffield , We have been very responsible for all details on our customers order no matter on warranty quality, satisfied prices, quick delivery, on time communication, satisfied packing, easy payment terms, best shipment terms, after sales service etc. We provide one-stop service and best reliability to our every customers. We work hard with our customers, colleagues, workers to make a better future.

The factory technical staff not only have high level of technology, their English level is also very good, this is a great help to technology communication.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top