Buy Fuji Feeder Product – ASM SIPLACE HF-3 FLEXIBLE HIGH-SPEED SMD PLACEMENT MACHINE, PICK AND PLACE MACHINE , CHIP MOUNTER, USED SMT MACHINE – RHSMT Detail:

HF-3

Flexible High-Speed SMD Placement

High flexibility, cost-effectiveness and set-up reliability guarantee that the SIPLACE HF/3 placement system will be highly productive. The minimal down times increase utilization, thus further in- creasing productivity.

INQUIRE NOW FOR MORE DETAIL >>>

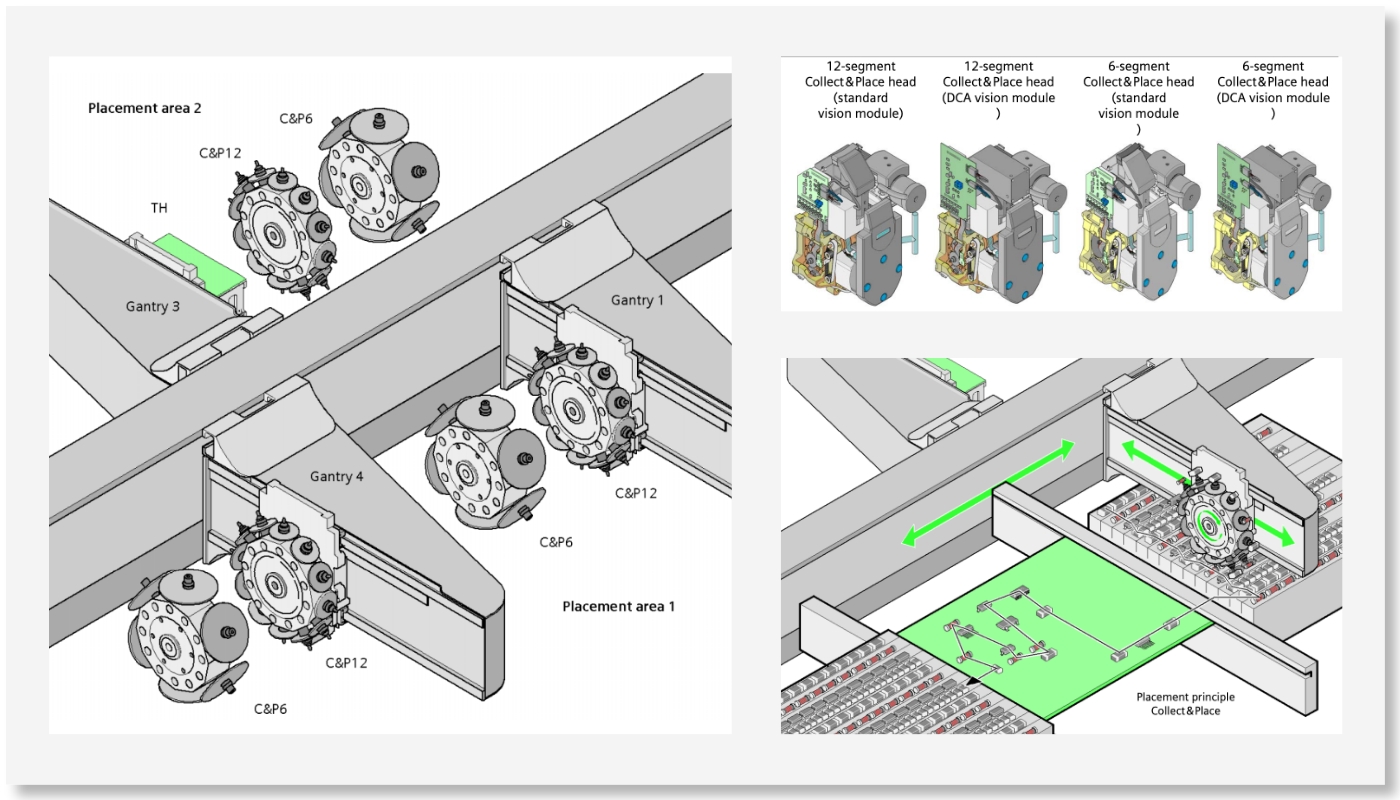

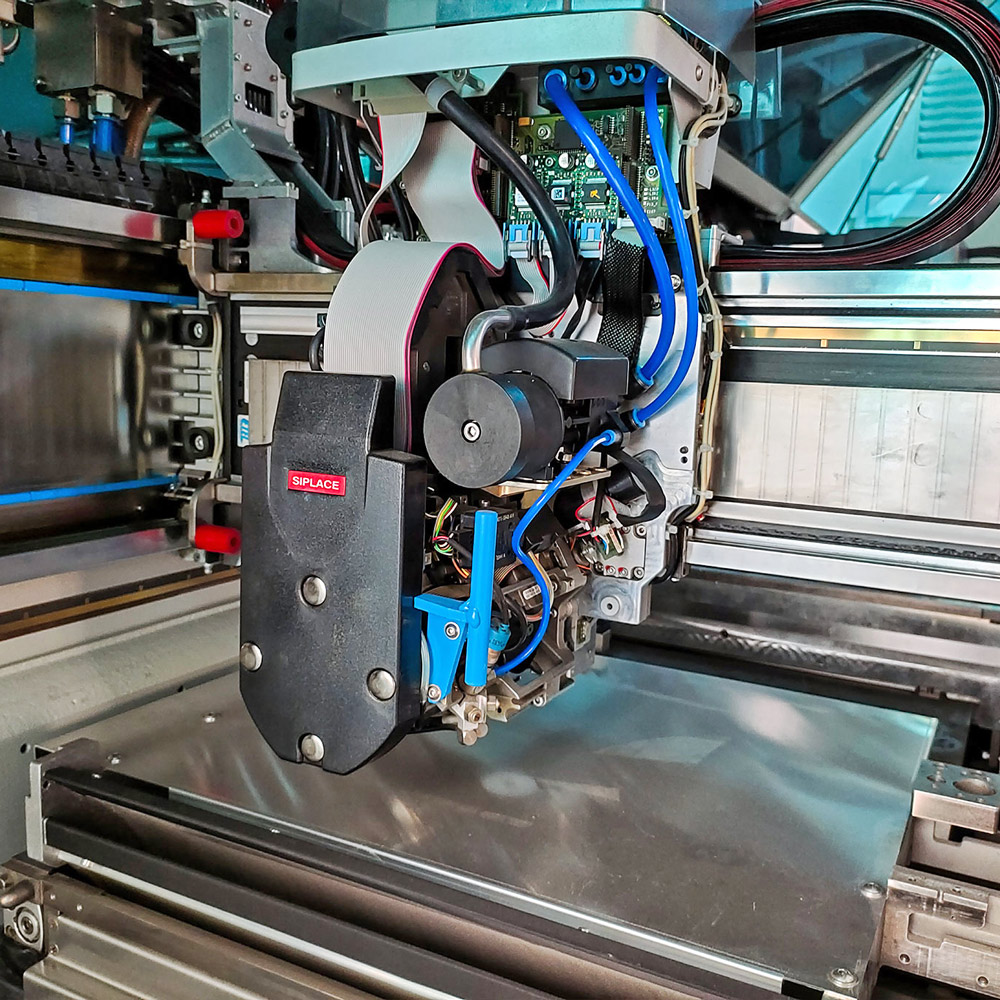

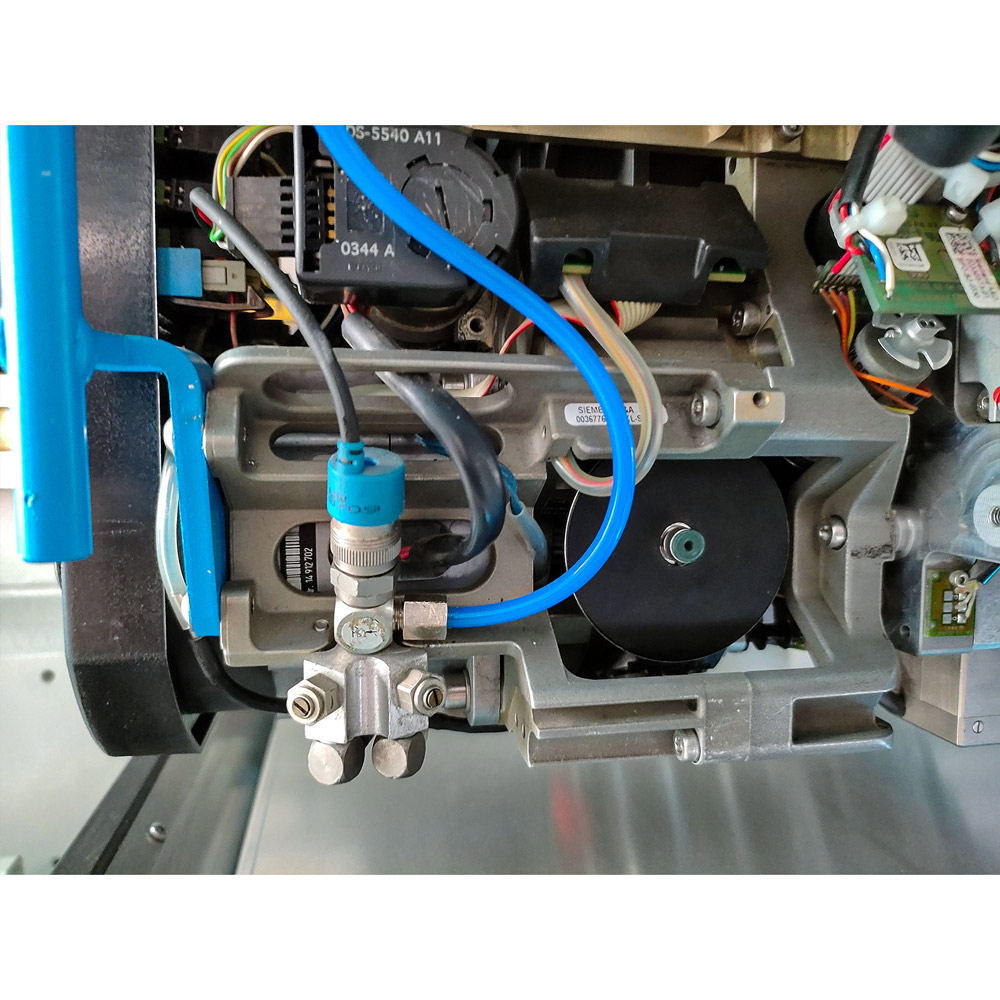

Placement Heads

• Twin Head picks up two components at the same time using the Pick&Place principle

→ increased speed when placing large components

→ greater flexibility due to broader range of components

• Head modularity

→ A simple placement head change adapts the machine to the current production requirements

• Reconfiguration kit

→ Local placement head change

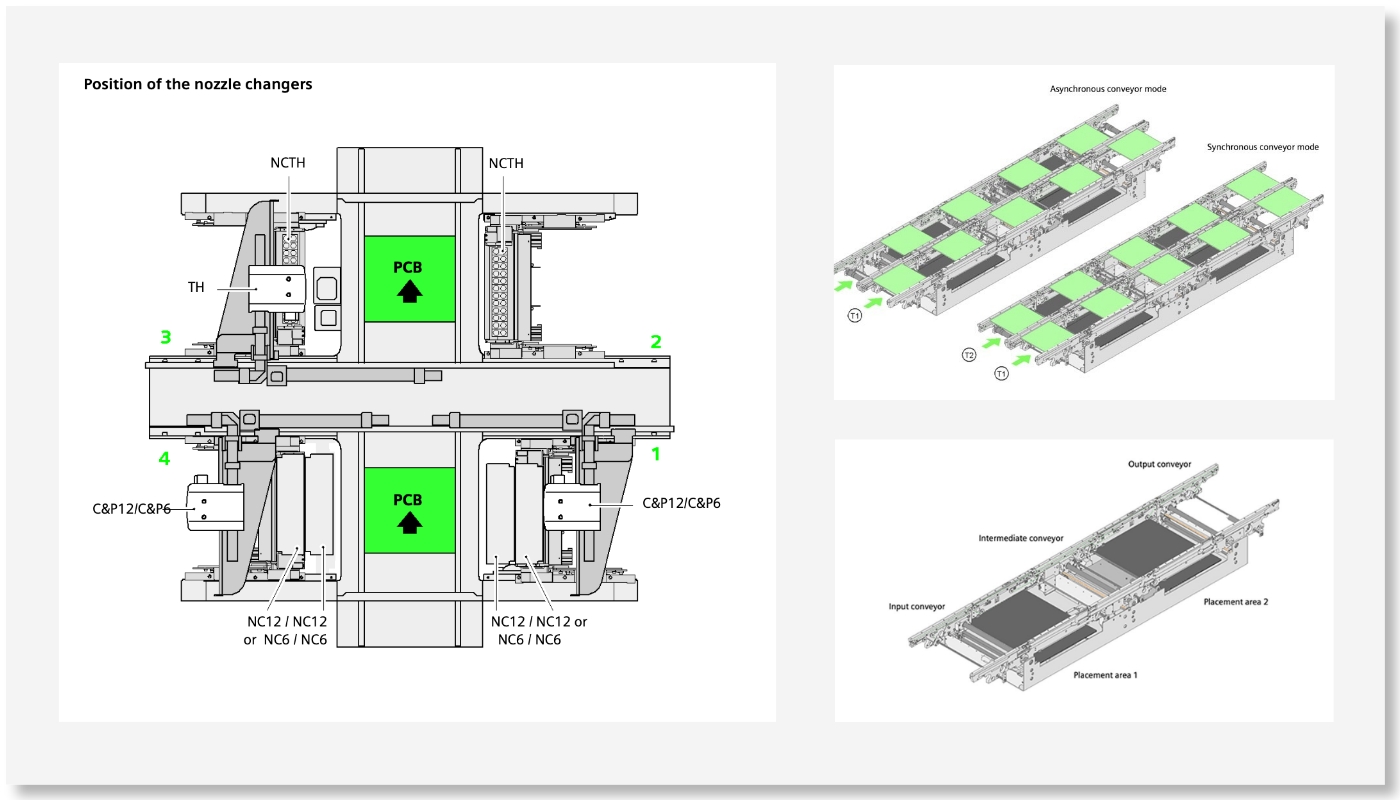

The PCB dual conveyor can greatly increase throughput with shorter down times – depending on the placement program. It allows two PCBs to be carried simultaneously (synchronously) or alternately (asynchronously) through the placement machine.

In asynchronous mode, only one PCB in a transport track is processed. At the same time, another PCB in the second transport track is moved into the placement position. This saves the full conveying timeof one PCB, thus considerably increasing performance, par- ticularly for PCBs with a short cycle time. The placement process starts as soon as one PCB is transported into the processing area.

In synchronous mode, two PCBs are moved into the placement position at the same time. They are pro- cessed as a common panel.

In this way, the top and bottom of a PCB can be pro- cessed on a single line. The proportion of non-productive time is reduced as two circuit boards are always conveyed simultaneously.

PCB Conveyor

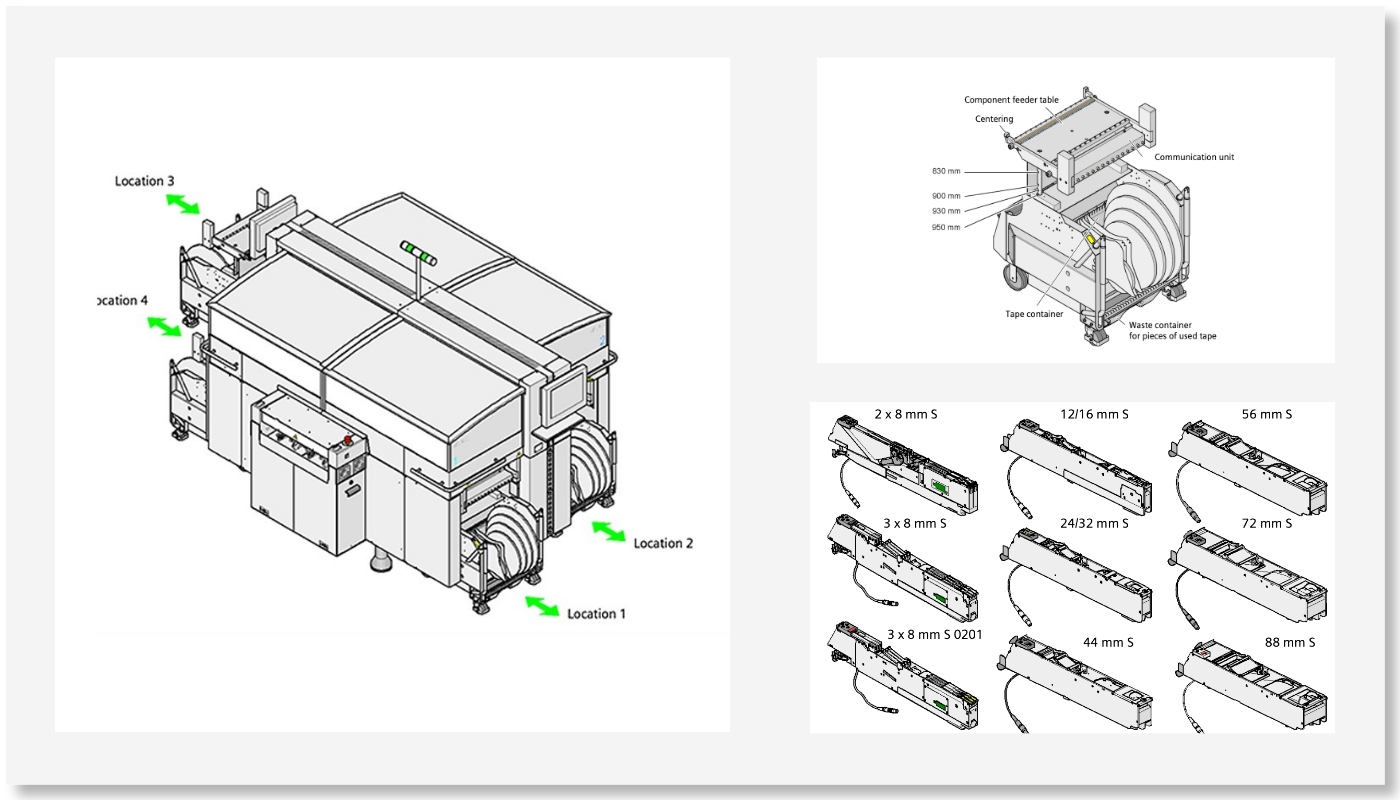

Component Feeding

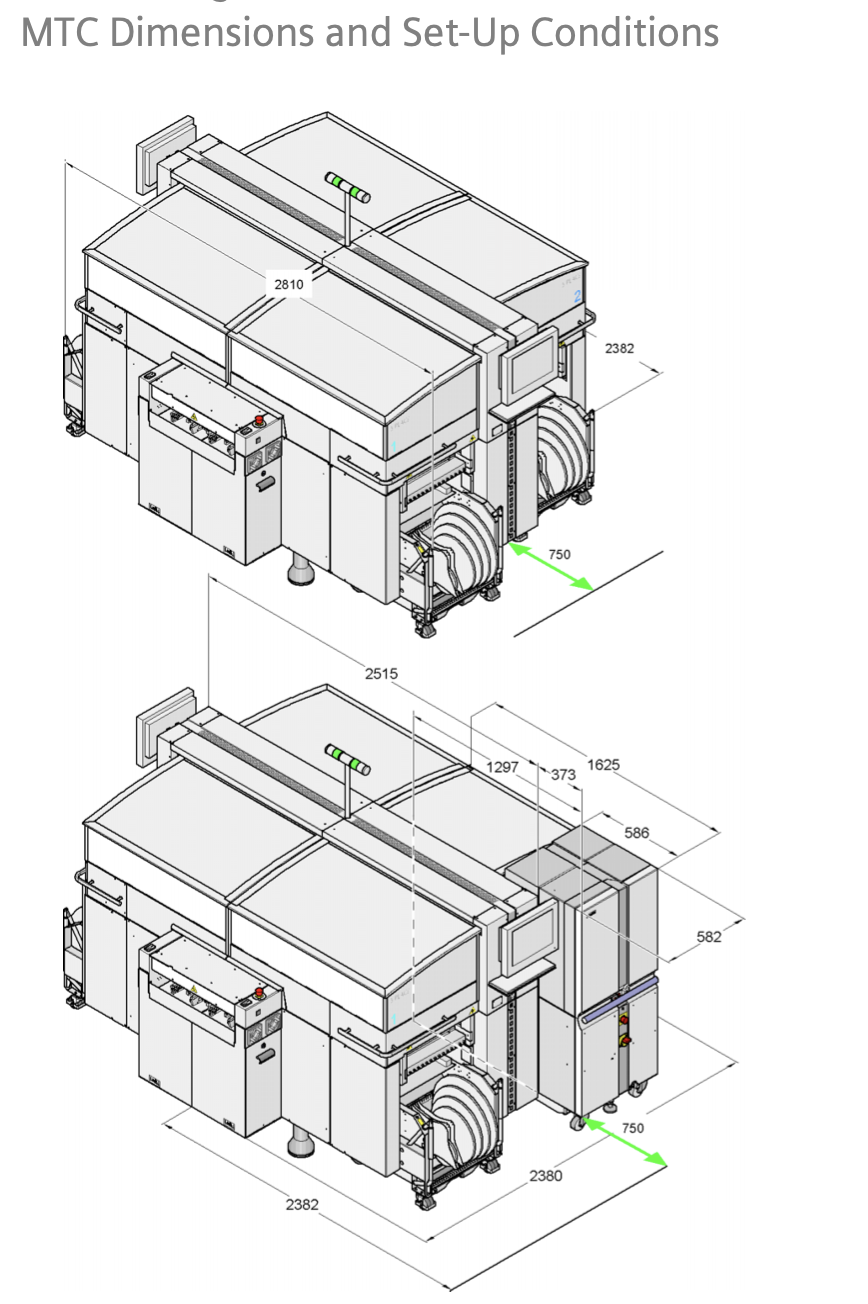

Up to four component changeover tables may be docked in the machine. Optionally, a matrix tray changer may be installed at location 2. The component changeover tables are stand- alone modules that can be set up at an external set-up area with feeders. In this way, changes only interrupt the production process for a short time. The chassis runs smoothly and is easy to maneuver. There are pockets for holding set-up list print- outs on both sides of the component changeover table. The operator has un- hindered access to the documents, even during production.

The component feeder table has a capacity of up to 15 locations for 30 mm wide feeders. The total capacity with four component changeover tables is thus 180 x 8 mm tracks.

Massive resources

We have in-depth cooperation with major SMT brands, most of the SMT equipment is in stock and can be shipped immediately

Quality assurance

All used equipment is tested, aged, and serviced before shipping. Vacuum packing in wooden boxes ensures safe delivery of equipment to you.

Secure transactions

We support flexible payment methods and a 6-month machine warranty to relieve your worries.

Trusted partner

We have many years of experience in the SMT field and are active members of IPC, your trusted partner!

Product detail pictures:

Related Product Guide:

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for Buy Fuji Feeder Product – ASM SIPLACE HF-3 FLEXIBLE HIGH-SPEED SMD PLACEMENT MACHINE, PICK AND PLACE MACHINE , CHIP MOUNTER, USED SMT MACHINE – RHSMT , The product will supply to all over the world, such as: Turkmenistan , Washington , Egypt , Our company has already had a lot of top factories and professional technology teams in China, offering the best products, techniques and services to worldwide customers. Honesty is our principle, professional operation is our work, service is our goal, and customers' satisfaction is our future!

The sales person is professional and responsible, warm and polite, we had a pleasant conversation and no language barriers on communication.

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top