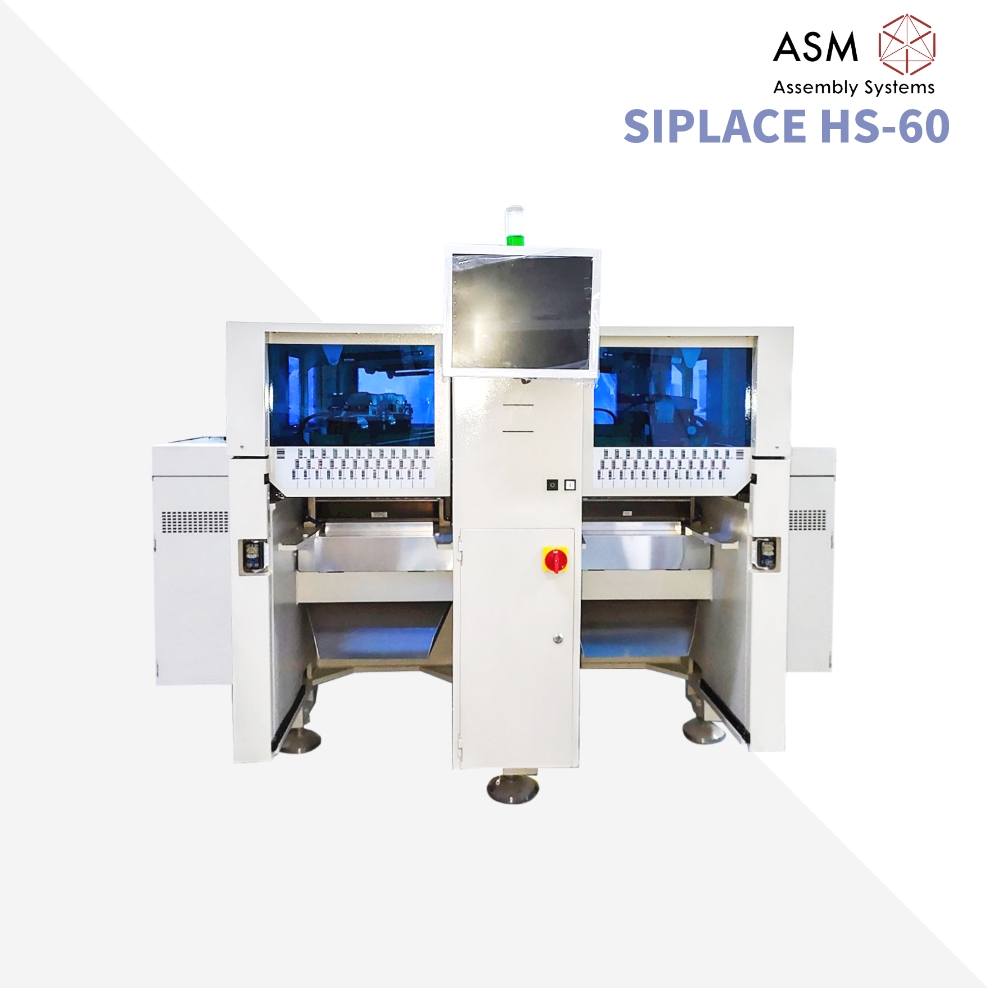

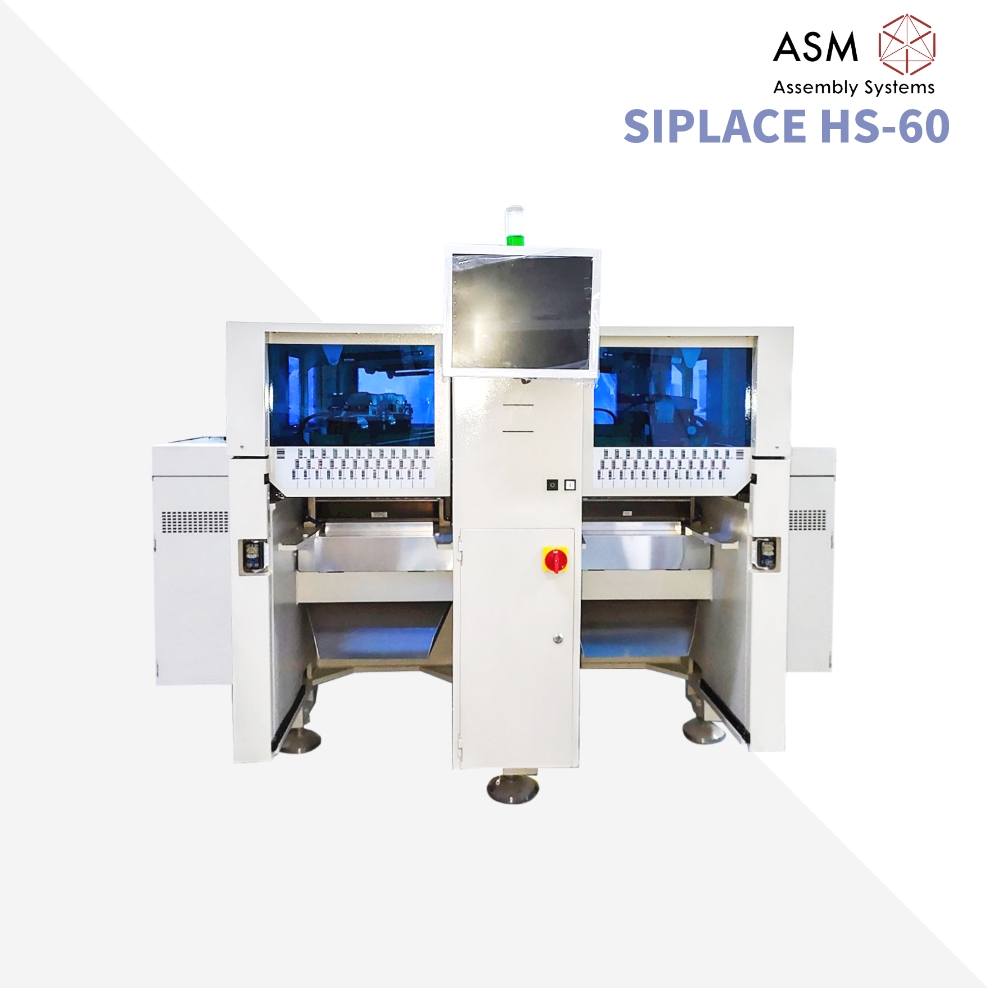

SIPLACE HF-60

ASM HIHG SPEED PLACEMENT MACHINE

Due to the efficient heads as well as the high acceleration the benchmark placement rate of 60,000 cph of the SIPLACE HS-60 is uncompared.

60,000 CPH

The SIPLACE HS-60 Very High Speed SMD placement system combines very high speed with both, accuracy and flexibility.Due to the efficient heads as well as the high acceleration the benchmark placement rate of 60,000 cph of the SIPLACE HS-60 is uncompared.

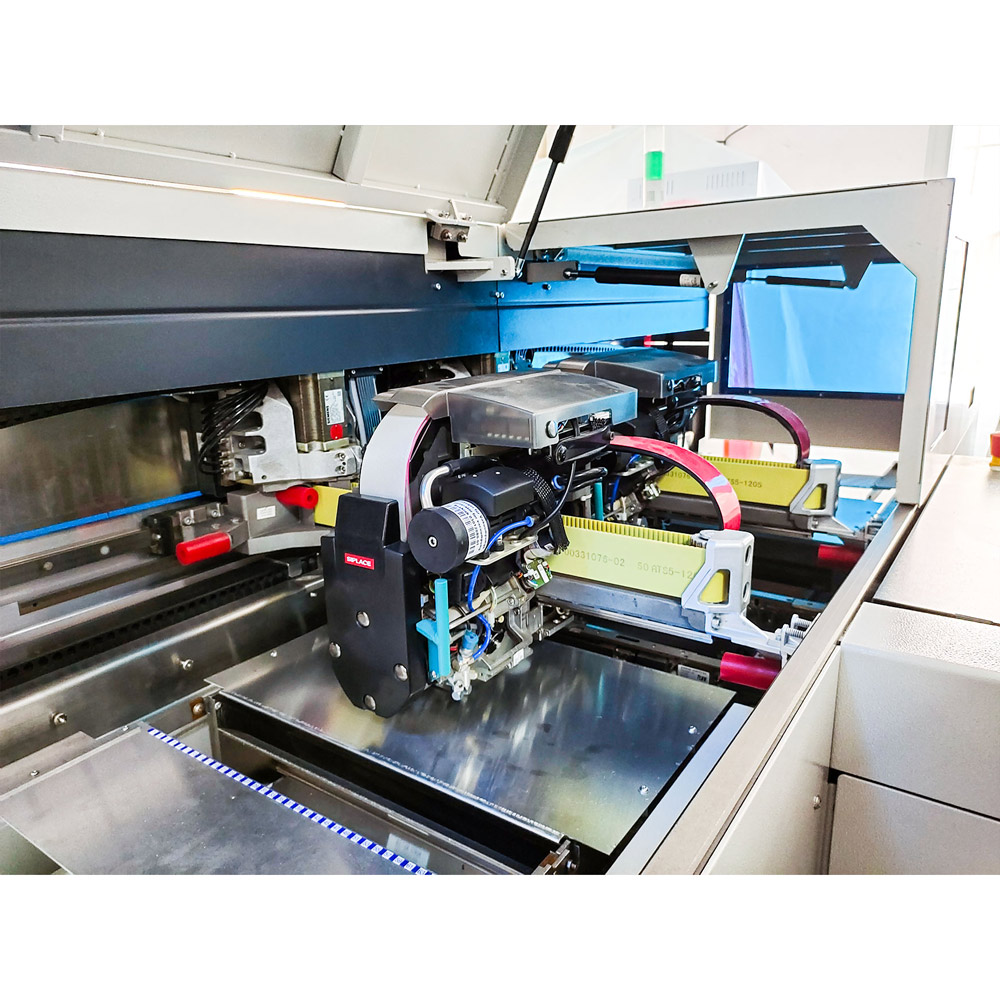

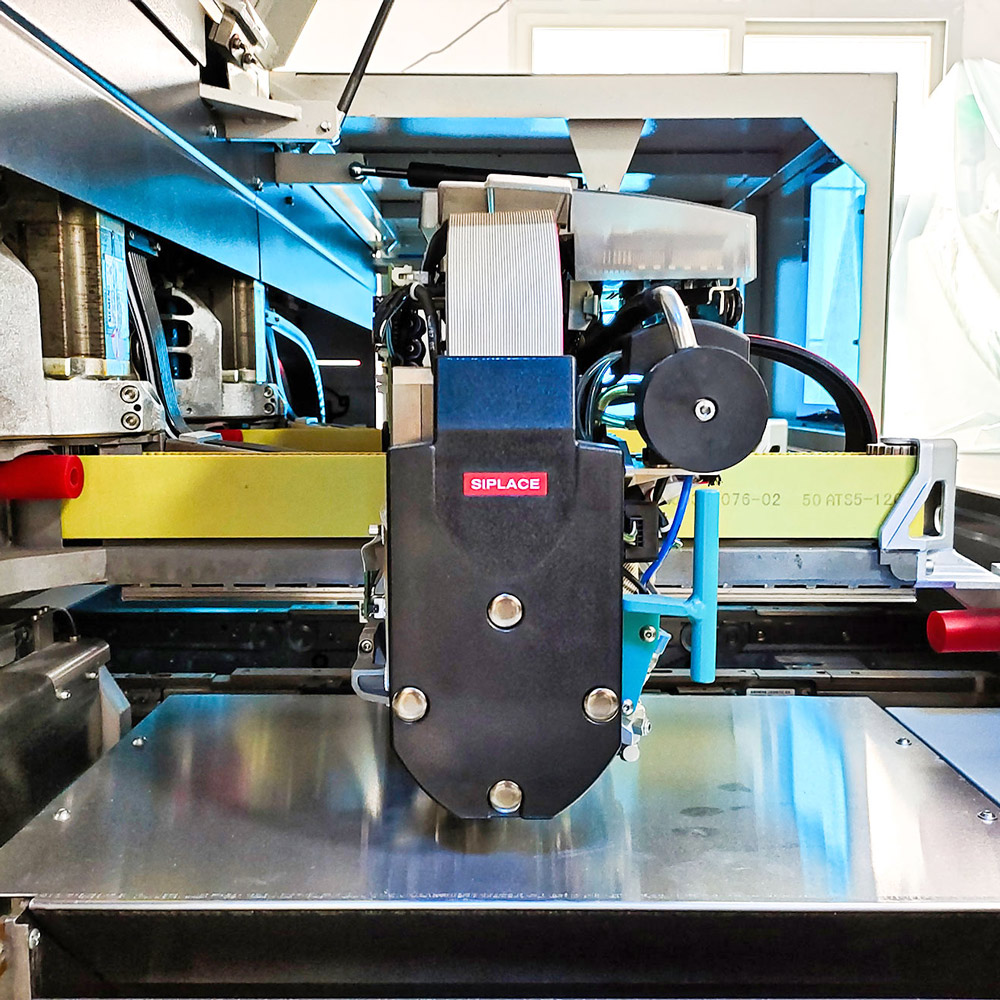

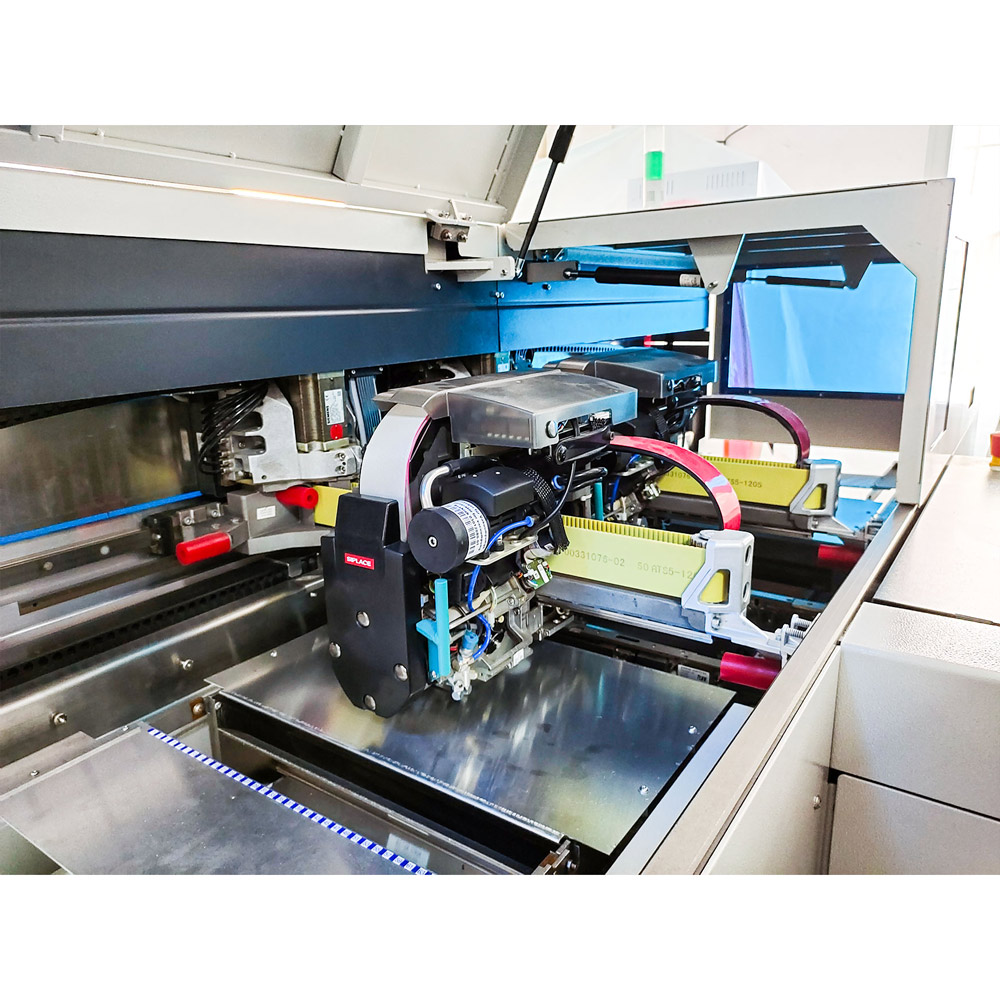

Speed coupled with economic efficiency and set-up reliability is the SIPLACE HS-60 is recipe for success. Components are already picked up as the PCB is transported into the placement area. The placement sequence is optimized for speed: While one Collect & Place Head is placing components, the second head is picking up the next series of components to be placed.

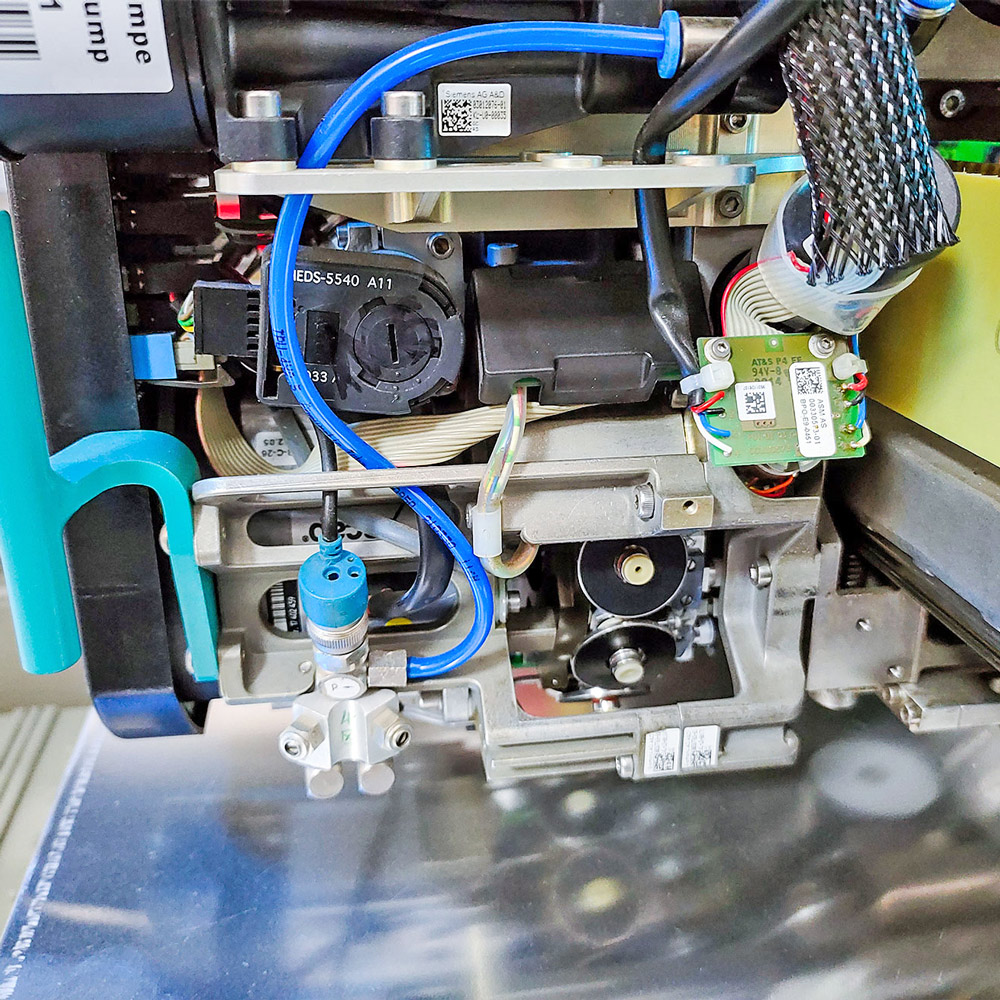

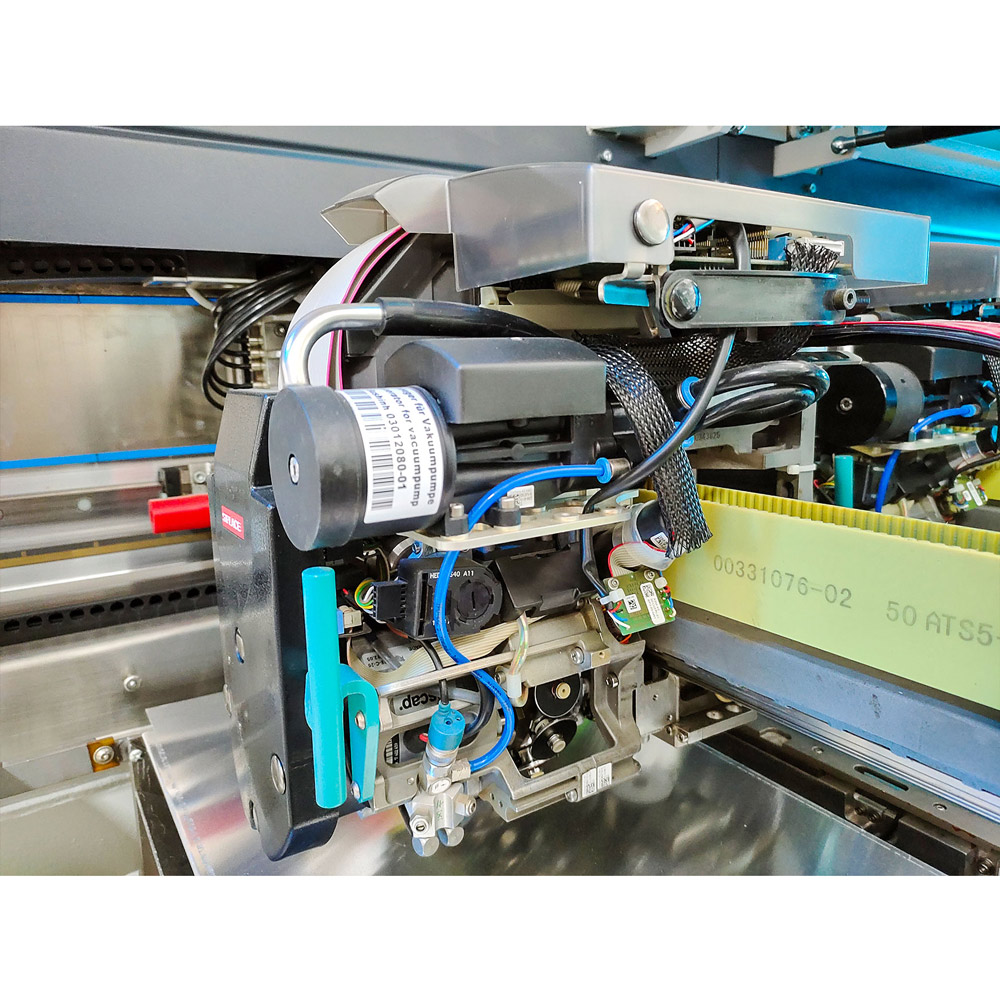

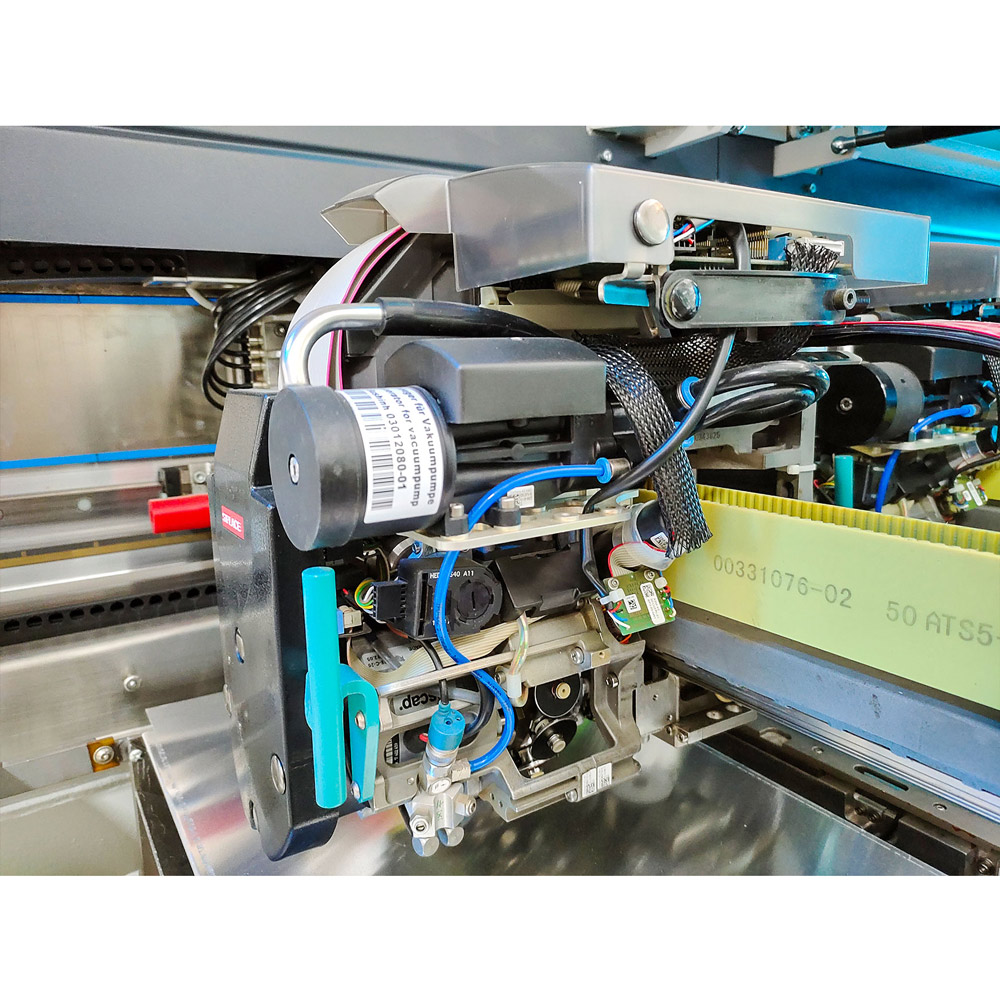

SIPLACE HS-60 machines are equipped with four X-Y-main gantries. Each gantry features a star-shaped 12-Nozzle Collect & Place Head. The placement heads alternately pick up com- ponents from a stationary feeder bank and place these components on the stationary PCB.

The innovative SIPLACE SMT platform guarantees maximum productivity. The fully modular concept allows quick adjustment and optimization to new productions. With SIPLACE you benefit from a global service network.

The highspeed placement system funds upon the modular SIPLACE platform and thus shows distinct advantages:

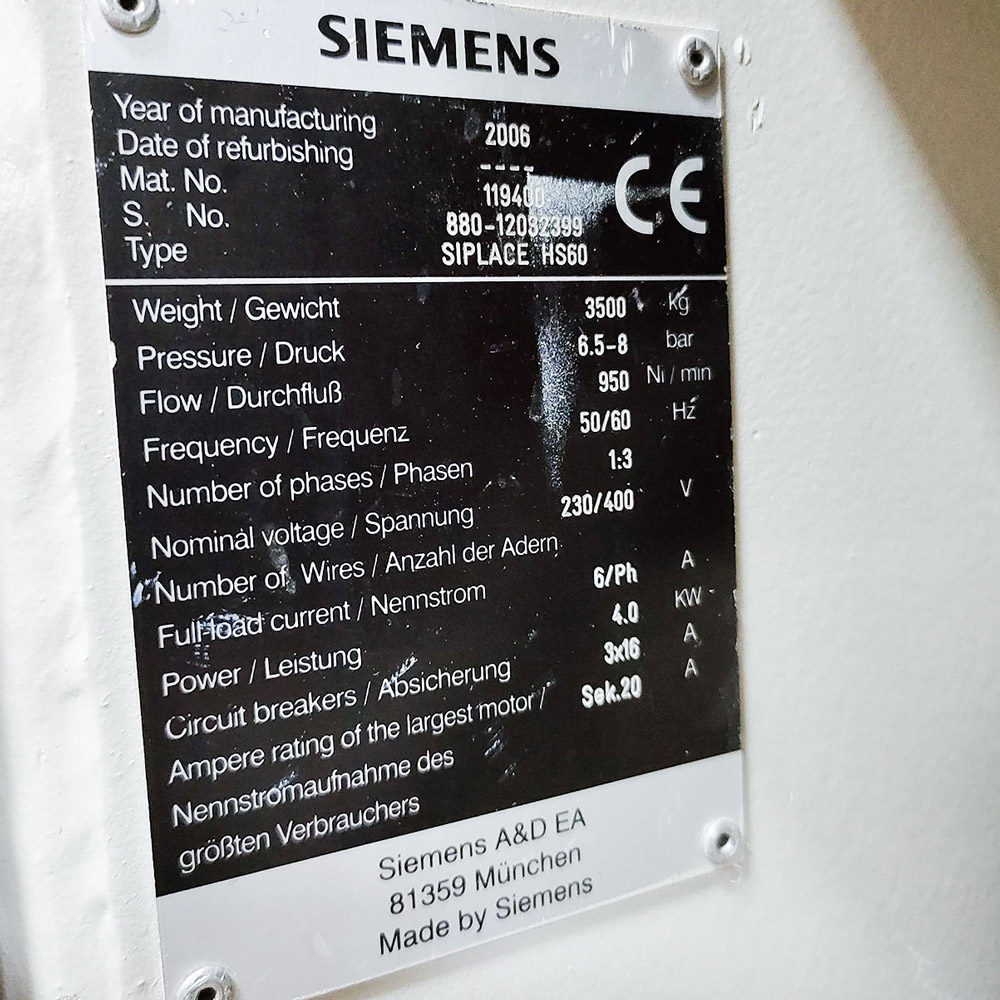

Technical Data

Among others, the following options are available for the SIPLACE HS-60:

- Additional changeover tables enables the reduction of job set-up time increasing machine utilisation.

- Dual Conveyor eliminates the non-productive PCB loading times thus increasing machines operating efficiency.

- Automatic nozzle changers for both changeover and storage of nozzles.

- PCB Barcode Reader used for product controlled production changeover.

- Component Bar Code Scanner used for feeder set-up verification

- Ceramic Substrat Centering.

- Component sensor.

For more details and information please see the SIPLACE HS-60 Specification.

| Type of placement head | 12-Nozzle Collect & Place Head |

| Number of gantries | 4 |

| Benchmark placement rate a | 60,000 cph |

| Component Range | 0.6 x 0.3 mm2 (0201) to 18.7 x 18.7 mm2 |

| Max. placement accuracy (at 4 sigma) a | 80/75 μm |

| PCB dimensions (L x W) | |

| Single conveyor | 50 x 50 mm2 to 368 x 216 mm2 / 2" x 2" to 14.5" x 8.5" |

| (optional up to 610 x 460 mm2 b) | |

| Dual conveyor | 50 x 50 mm2 to 368 x 460 mm2 / 2" x 2" to 14.5" x 18" |

| (optional up to 610 x 216 mm2 b) | |

| Feeding capacity | 144 tracks, 8 mm tape |

| Component table | Quick changeover table with integrated wheels, reel holder and scrap bin |

| Types of Feeder modules | Tapes, Bulk Cases, Surf Tape feeders, application-specific OEM feeders |

| Operating system | Microsoft Windows / RMOS |

| Power | 4KW |

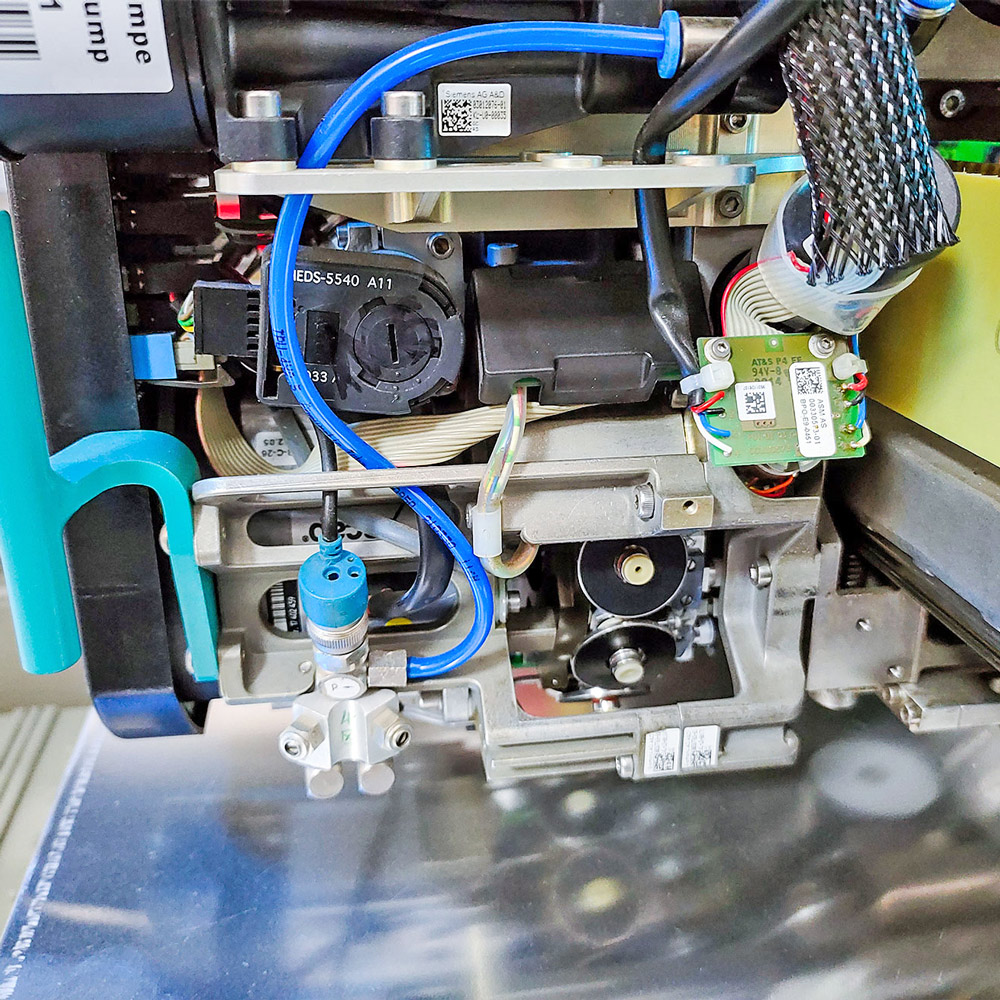

| Compr. air requirements | 6.5 - 10 bar, 950 Nl/min, tube 3/4'' |

| Vacuum pump (Option) | 6 - 10 bar, 400 Nl/min, tube 3/4'' |

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top