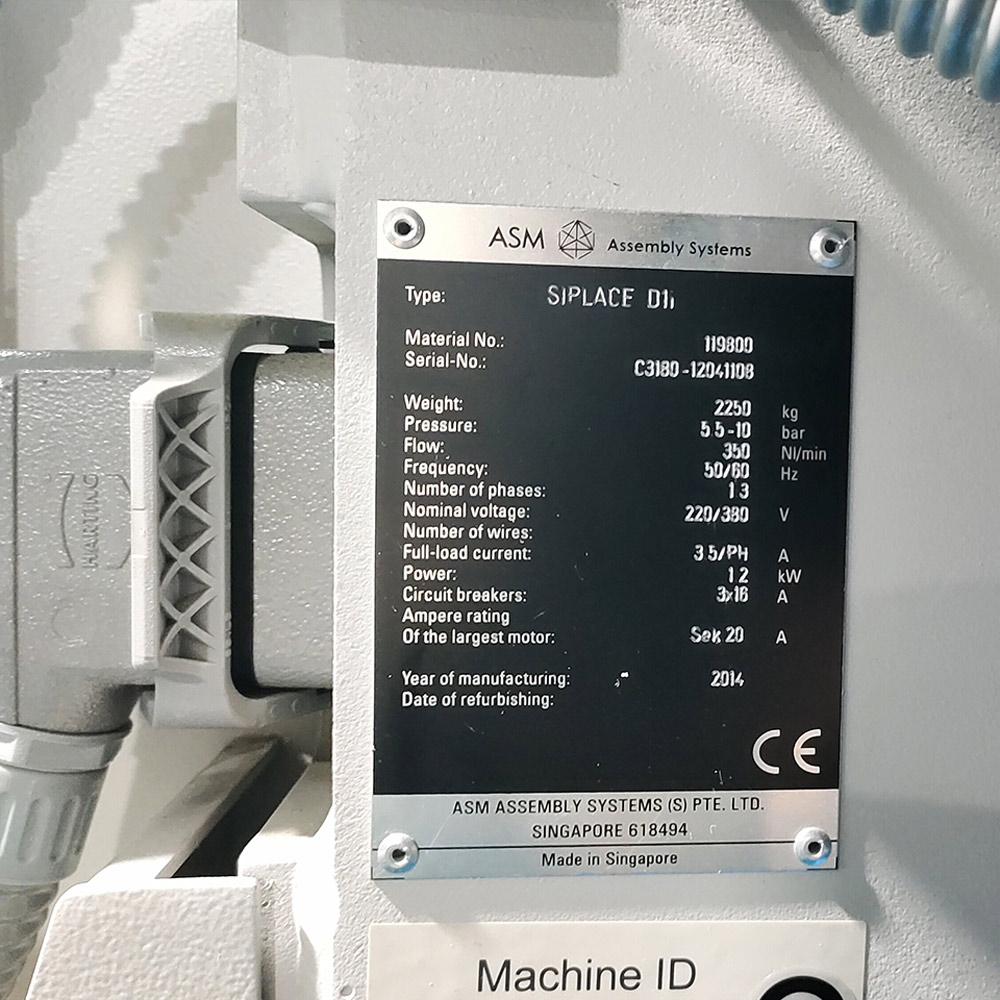

SIEPLACE D1i

ASM HIHG SPEED PLACEMENT MACHINE

Used ASM SIPLACE placement machine on stock , good condition , good price

20,000 CPH

Theoretical value

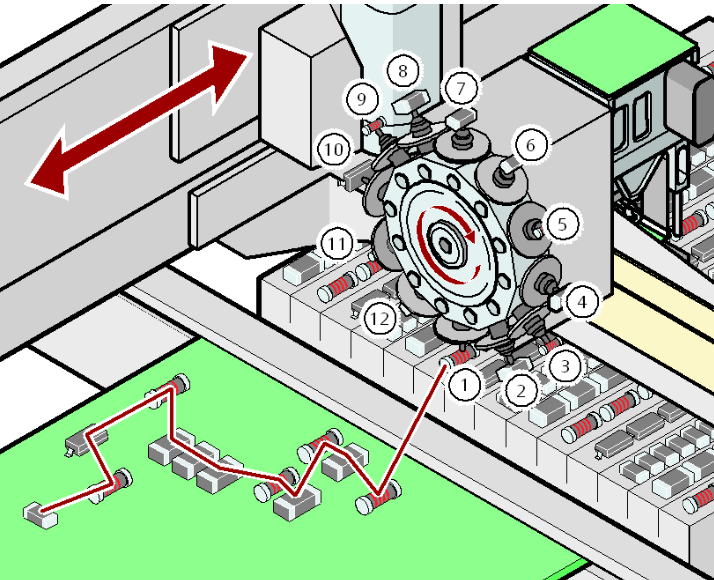

Collect&Place principle

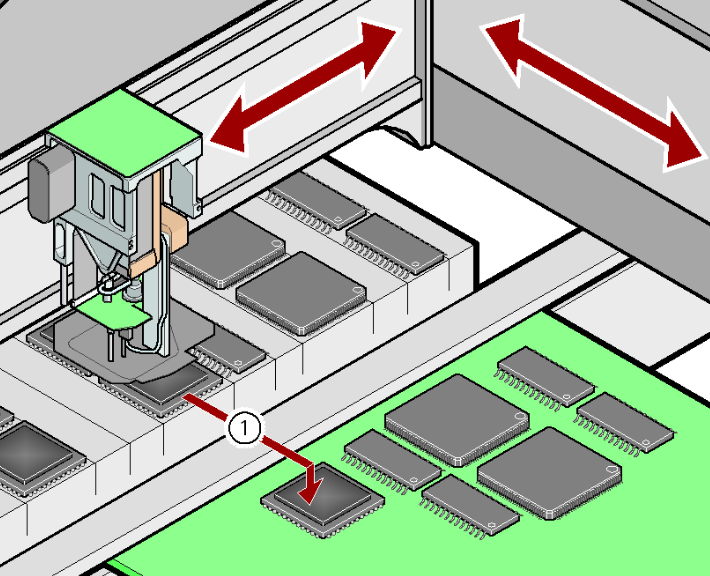

Pick&Place principle

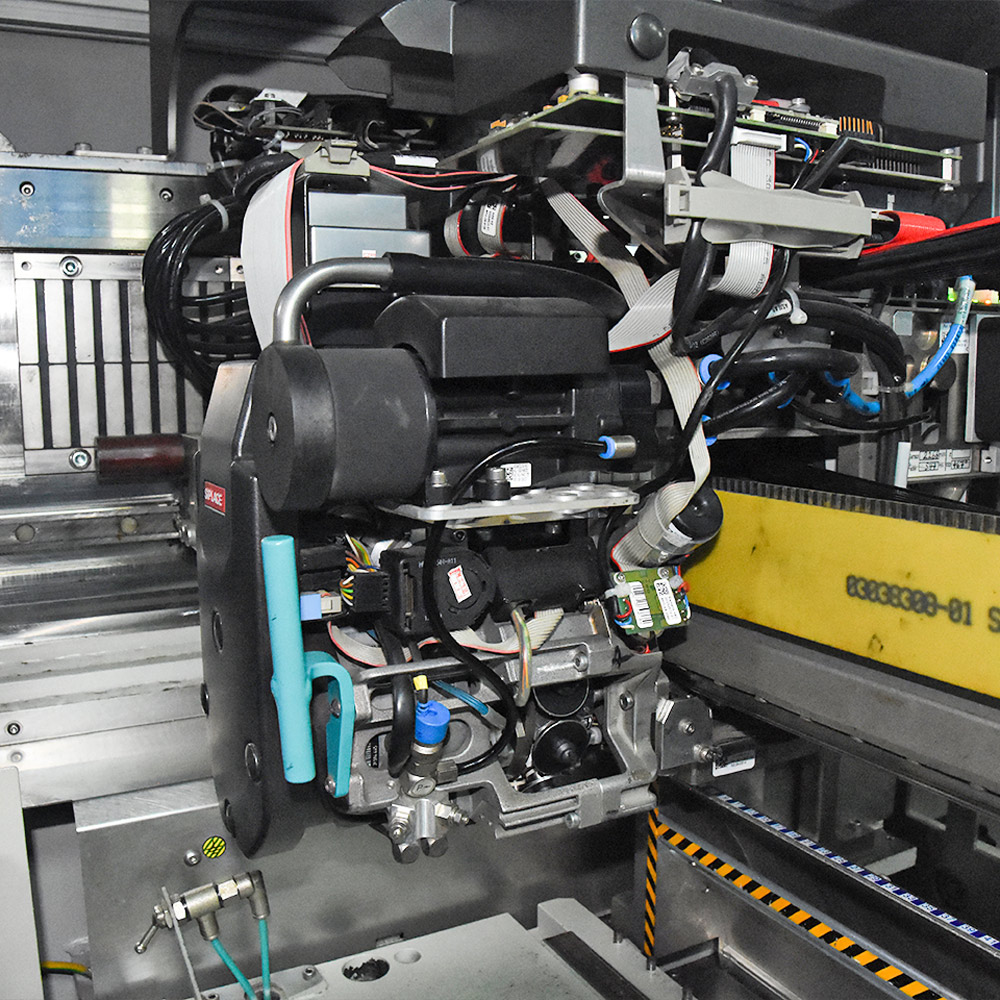

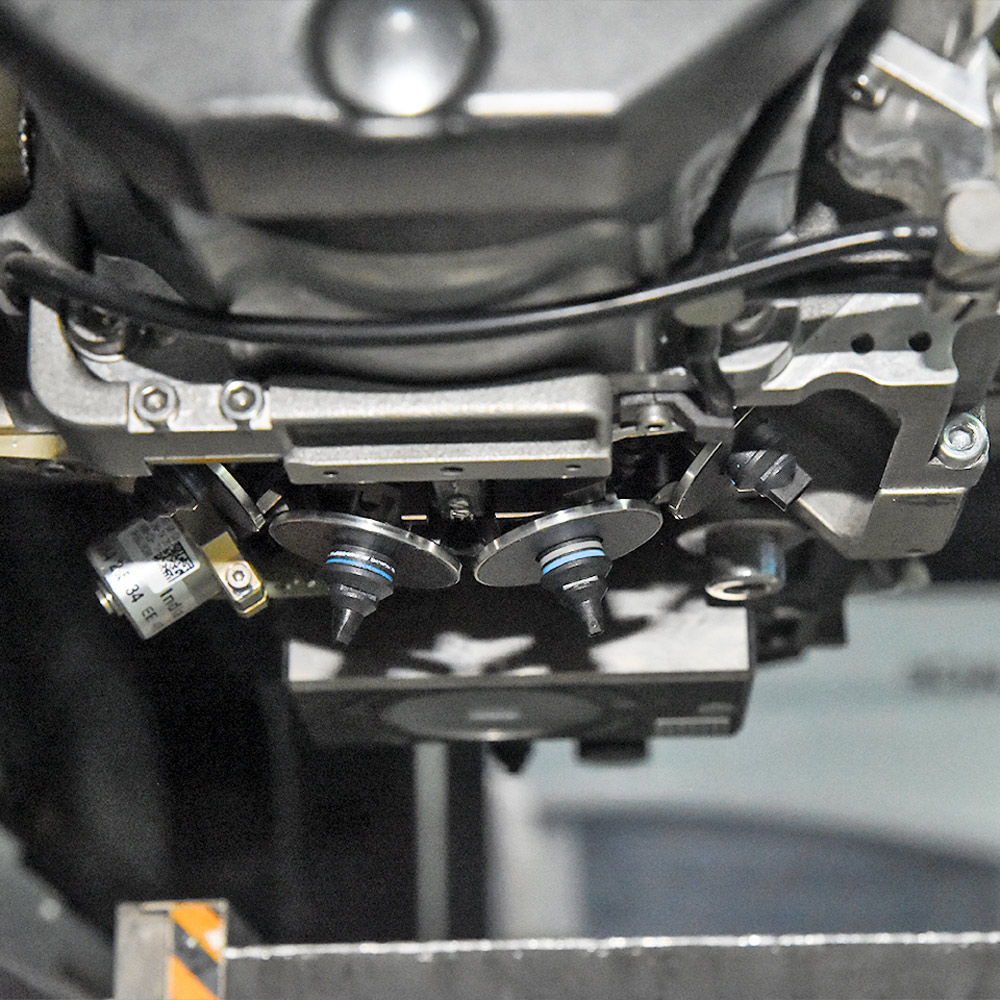

Placement Head

The SIPLACE D1i is charac- terized by maximum flexibil- ity in the production process.

This flexibility is partly due to the head modularity of the placement machine as it allows different placement head variants to be config- ured to suit the production requirements. The gantry on the SIPLACE D1i can be equipped with one (as a SIPLACE D1iS) or two (SIPLACE D1i) placement heads, as required. The fol- lowing placement head con- figurations are possible:

Operation with two place- ment heads:

• C&P12 and P&P head

• C&P6 and P&P head

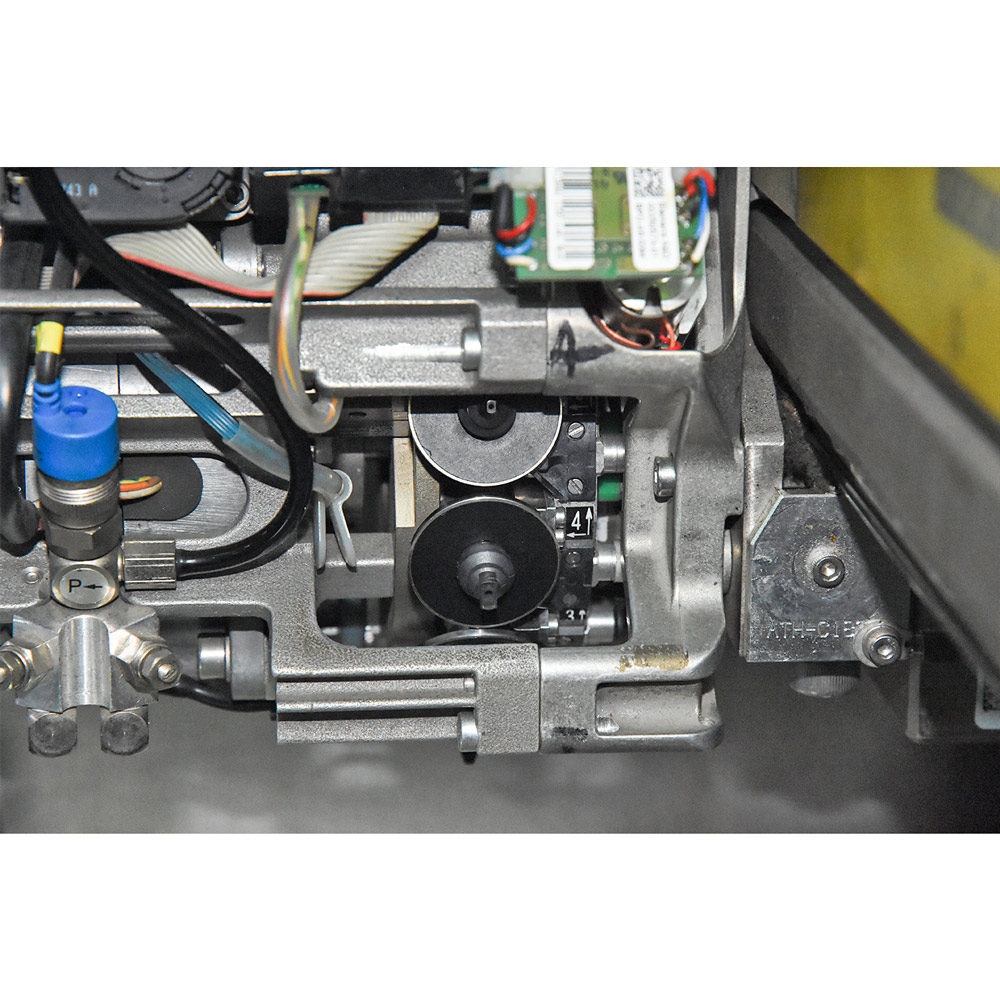

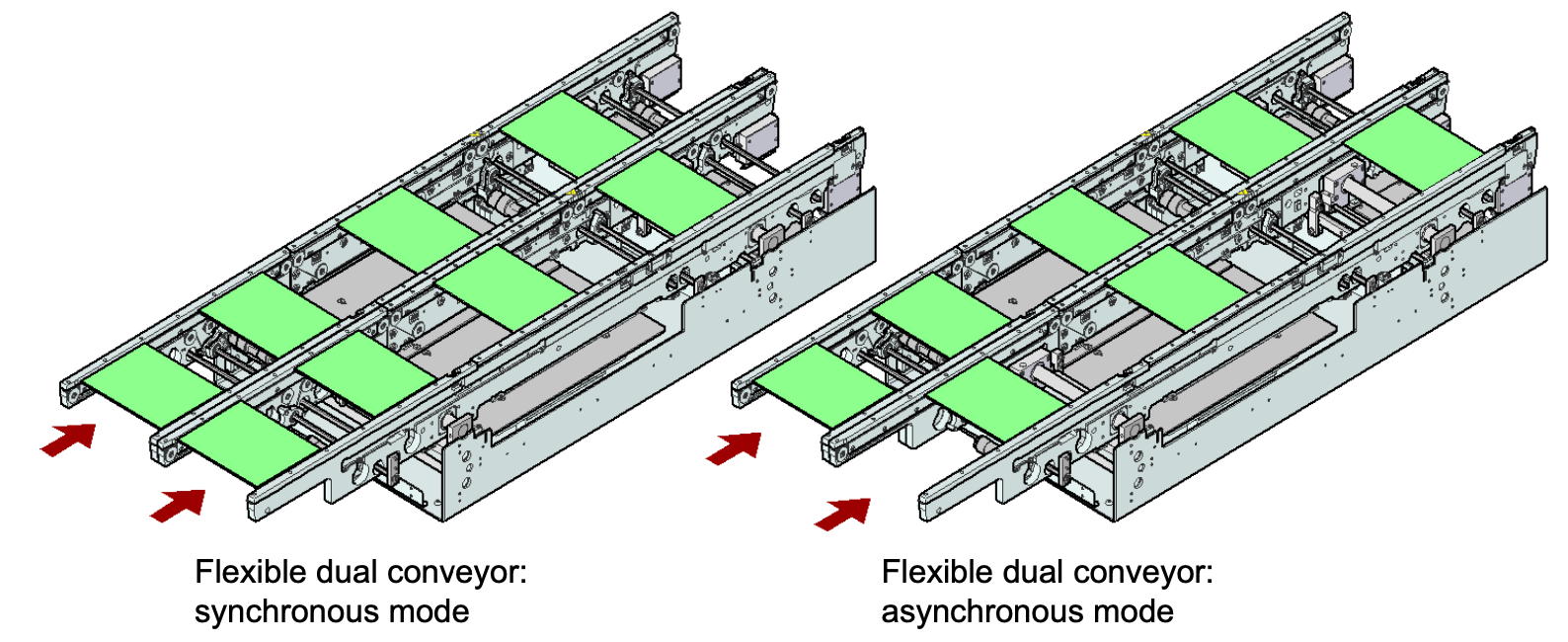

Conveyor principle

If the board has reached the placement area and passed a light barrier, it is braked. An additional laser light barrier determines the position of the board. As soon as the circuit board has reached its target position, the conveyor belt is stopped and the board is clamped from below. The placement process then starts immediately. Movement and clamping of the PCBs are monitored.

The conveyor can be easily matched to many different PCB widths. The fixed conveyor rail may be located on the left or right for both the flexible dual conveyor and the single conveyor.

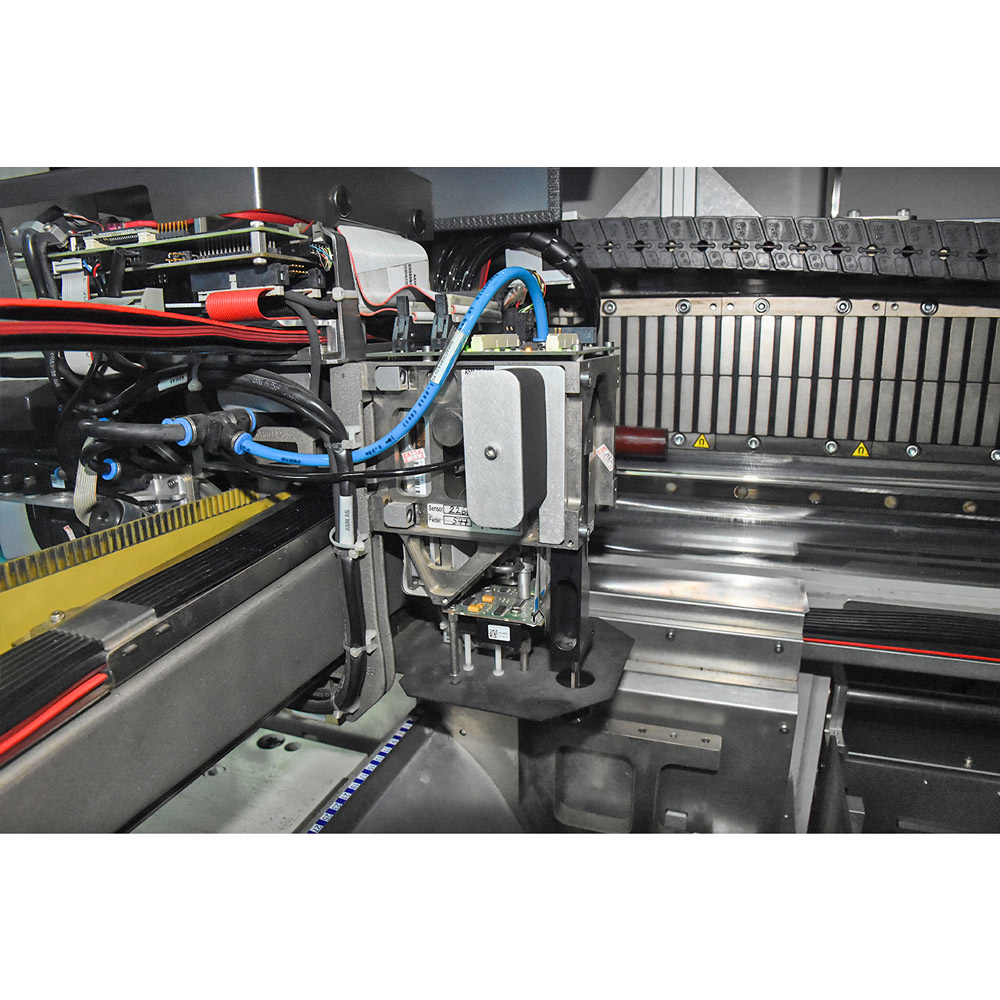

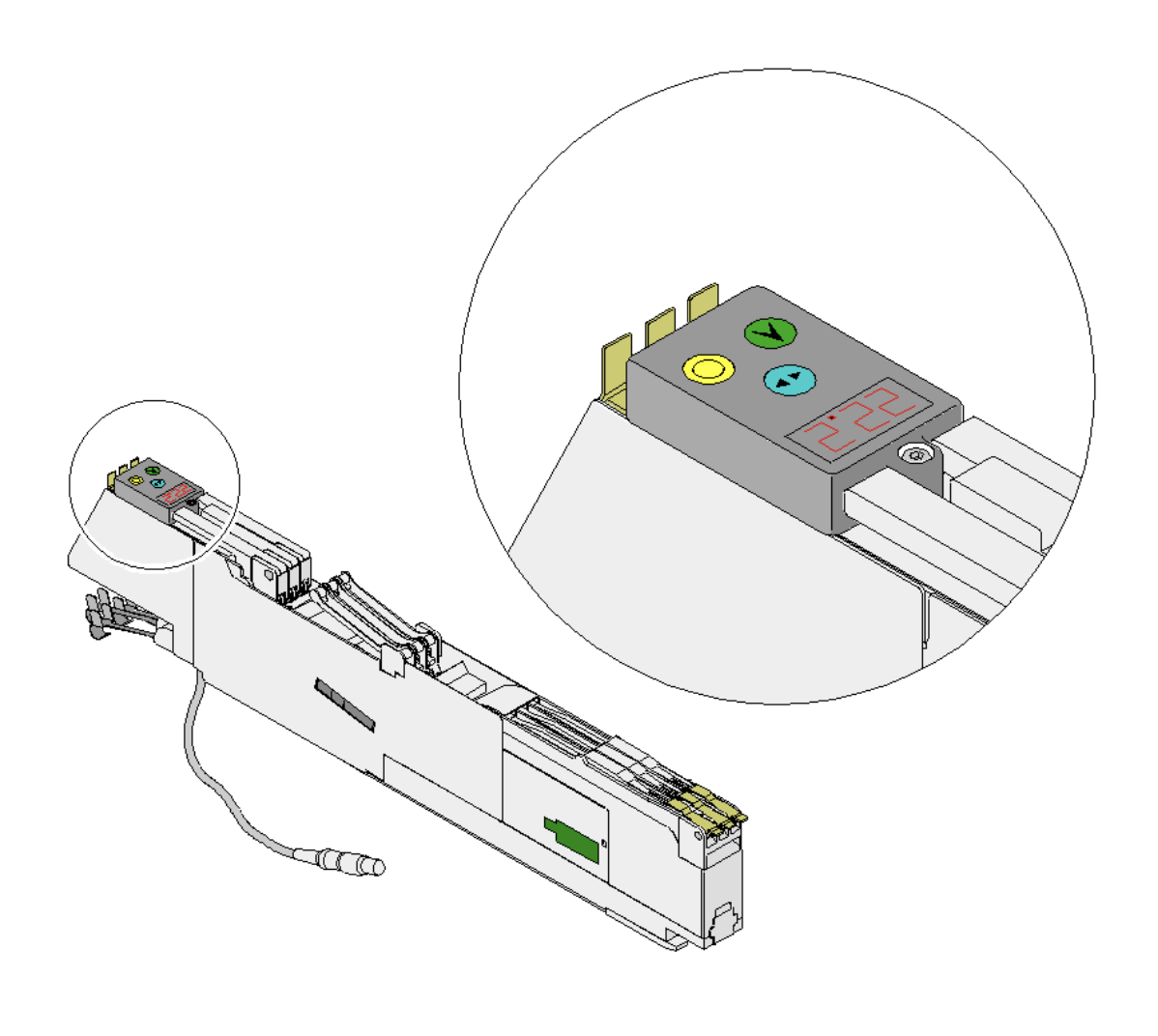

S Tape Feeders

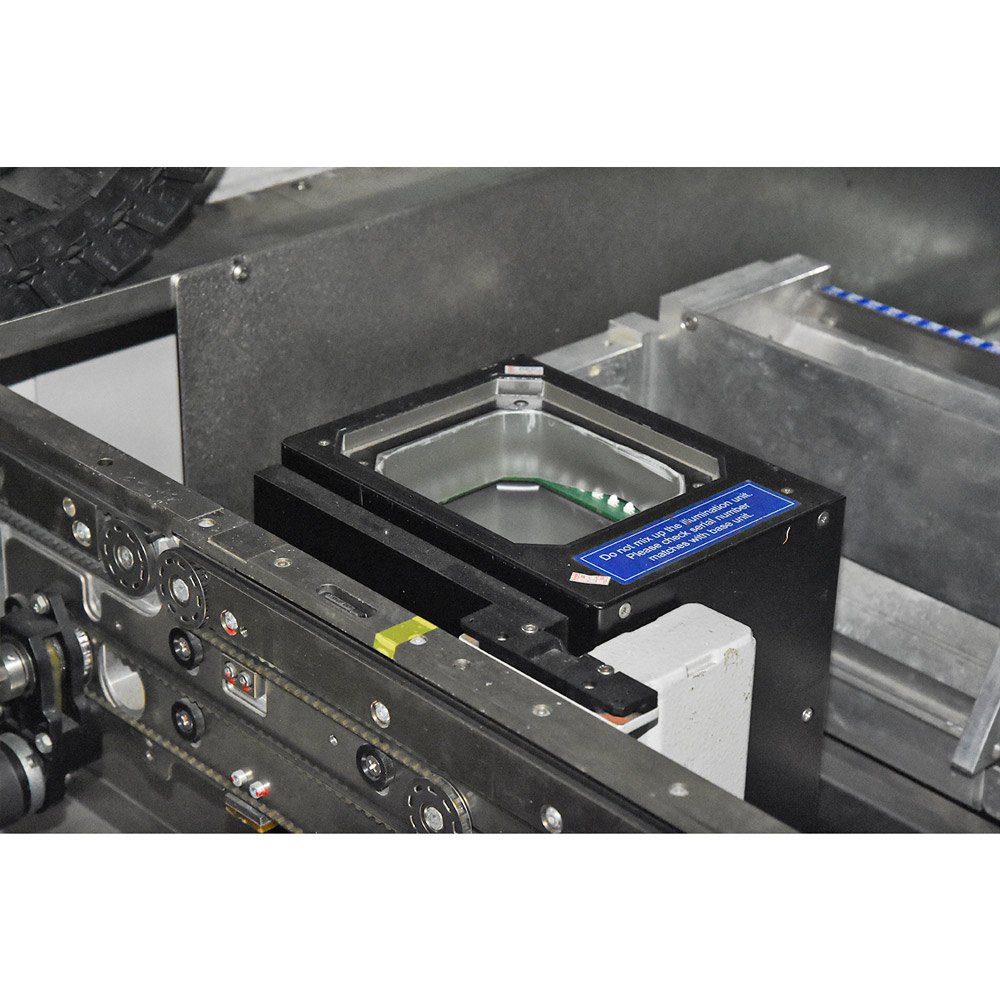

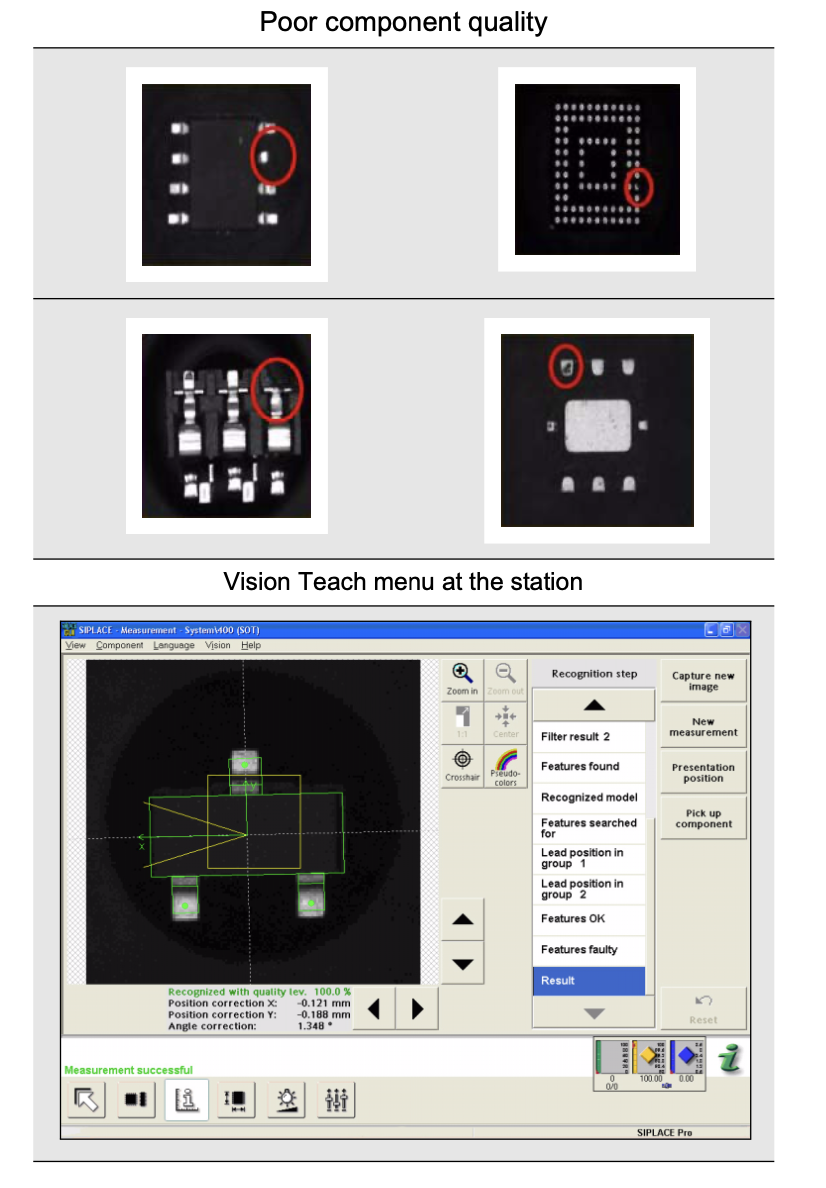

Digital Vision System

The digital SIPLACE vision system automatically saves the last 500 images of components that were identified as "bad". SIPLACE users can then easily demonstrate poor component quality.

The benefits at a glance:

• Maximum placement quality

• High first pass yield

• Reduced operating costs

Products categories

-

Phone

-

E-mail

-

Whatsapp

Whatsapp

-

WeChat

Judy

-

Top